|

|||||||

Qarmet is the only long process steel conglomerate in Central Asia and a pillar of Kazakhstan's industry. It has significant influence in the Central Asian steel industry and is also one of ACRE's important overseas customers. The signing of this agreement marks another landmark achievement of the cooperation between China and Kazakhstan, and also injects new momentum into the upgrading of the green metallurgical industry in Central Asia.

On November 4th, 2024, the Prime Minister of Kazakhstan, Bekkenov, attended the Kazakhstan China Investment Roundtable in Shanghai and held talks with representatives from leading enterprises in metallurgy, energy, engineering machinery, coal chemical industry, agricultural and industrial complexes, pharmaceuticals and other industries in Kazakhstan and China.

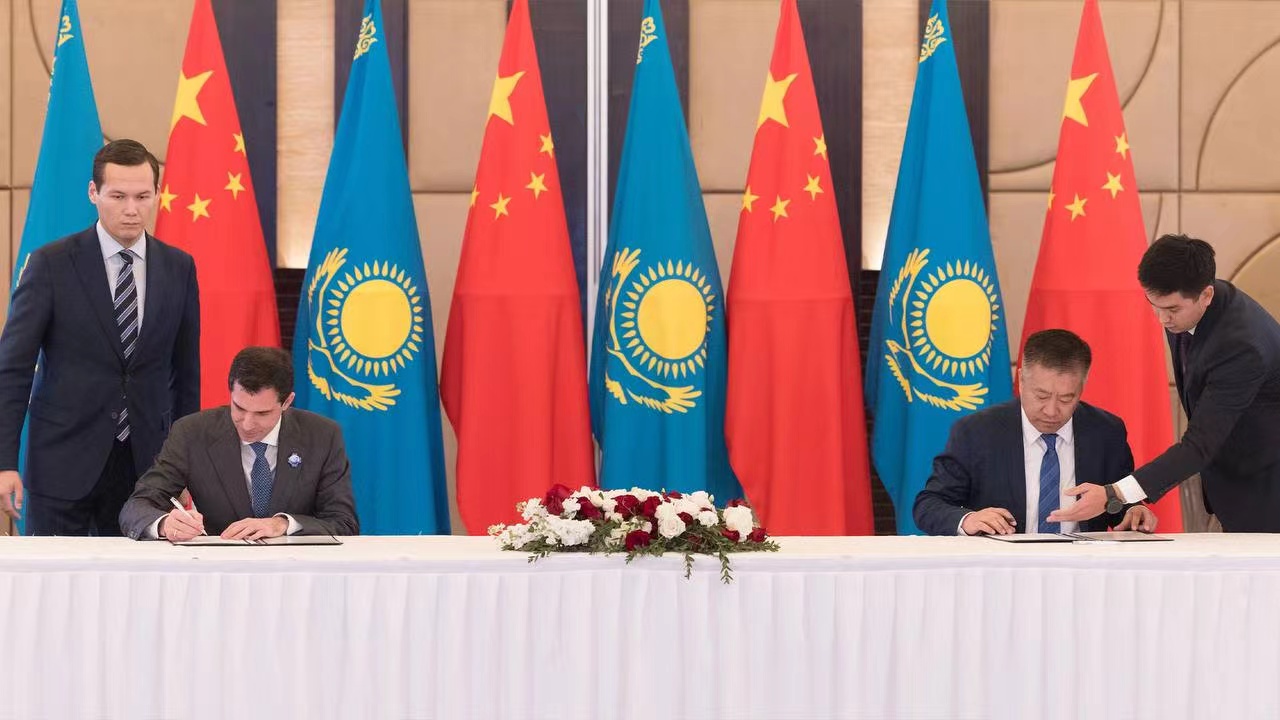

At the meeting, Yang Zhongyi, Chairman of ACRE, signed a cooperation agreement with Qarmet and spoke as a representative of ACRE. Yang Zhongyi stated that ACRE will take this cooperation with Qarmet as an opportunity and a new historical starting point to provide Kazakhstan with green, low-carbon, intelligent, efficient, safe and stable technology and equipment. Through the full process of coking technology services and first-class solutions, it will create a new benchmark for Kazakhstan's coking industry and contribute wisdom and strength to Kazakhstan's economic development and the friendship between China and Kazakhstan.

At the signing ceremony, Zhang Shuang, General Manager of ACRE, and Basin, Chairman of Qarmet, jointly opened a new era of cooperation. Zhang Shuang stated that as a leading enterprise in the global coking engineering technology field, ACRE will demonstrate the hard core strength of Chinese technology in this project. The 7.6-meter top charging coke oven used in this project is a brand new coke oven tailored by ACRE for Qarmet based on the most advanced technology in the industry. It not only significantly improves production efficiency, but also achieves significant reductions in energy consumption and pollutant emissions. This project integrates advanced process technology and equipment, intelligent production, efficient waste heat recovery, and full process environmental protection management solutions, reflecting the deep integration of "green coking" and "digital intelligence".