|

|||||||

Lime Kiln Technology

With the purpose of energy saving, environmental protection and comprehensive use of resources, and based on over 60 years of experience on the development, design and construction of kiln, ACRE has provided more than 80 rotary kilns and 170 shaft kilns for customers both at home and abroad.

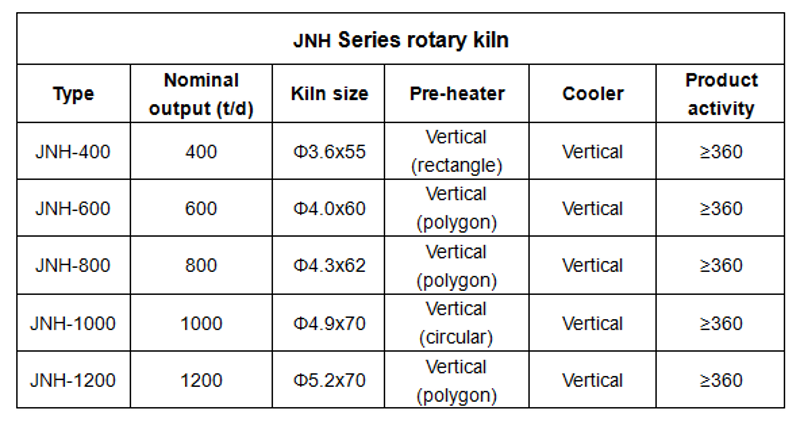

Main technical parameters of JN series rotary kiln

NOTE: ACRE is able to design rotary kiln with parameters other than the ones listed in the above table according to the requirement of customer.

ACRE owns the technology of a series rotary kiln with production rate of 400~1200t/d, and made several innovation and improvement on preheater, rotary kiln and cooler, based on many years of practical experience, and by adopting the methods of 3-D design, .structural mechanics analysis and simulation. This technology has been broadly adopted by customers as it has the advantages of large output, high quality product, energy conservation and high automation level.

Main technical parameters of JNS series shaft kiln

Basing the development of new technologies on many years of design and practical experience, and considering the technical features of several kiln types, ACRE has developed large double shaft kiln which can produce high quality lime with less heat consumption, low cost large gas-firing shaft kiln using low calorific gas as fuel, and multi-fired shaft kiln using coke or anthracite as fuel which has the advantages of convenient operation and low cost.

Lime Making Technology

The basic process of lime making includes material washing and screening, firing, crushing and screening of final product, lime briquetting, and lime passivation, etc.. ACRE can provide the whole process design for the lime making systems, and owns the intellectual property rights on all JNH series rotary kilns with capacity of 400~1200 t/d, and is technically predominant in the development of various JNS shaft kilns with capacity of 100~800 t/d and large scale non-standard equipment.