Coking Wastewater Treatment and Reuse Technology

Technical Features:

①Widely applied to iron & steel complex and independent coking plant both home and abroad;

②Full-fledged technology, stable operation and high level of automation;

③Comprehensive use of treated wastewater, in compliance with requirement for fresh water consumption and discharge water quantity per ton of coke production regulated in national standard GB16171-2012.

Three individual technologies:

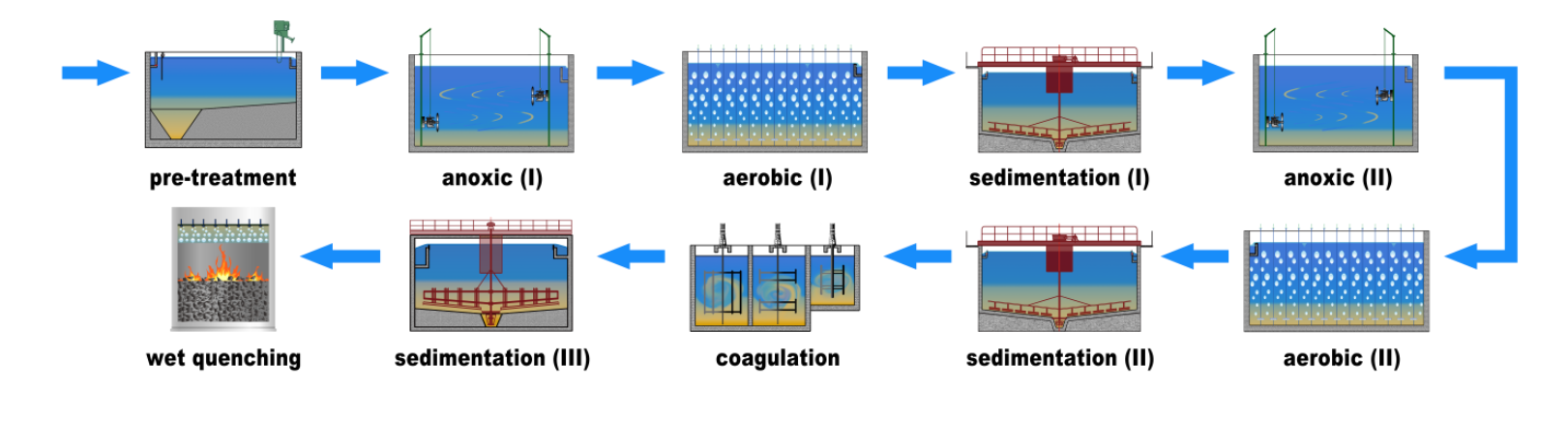

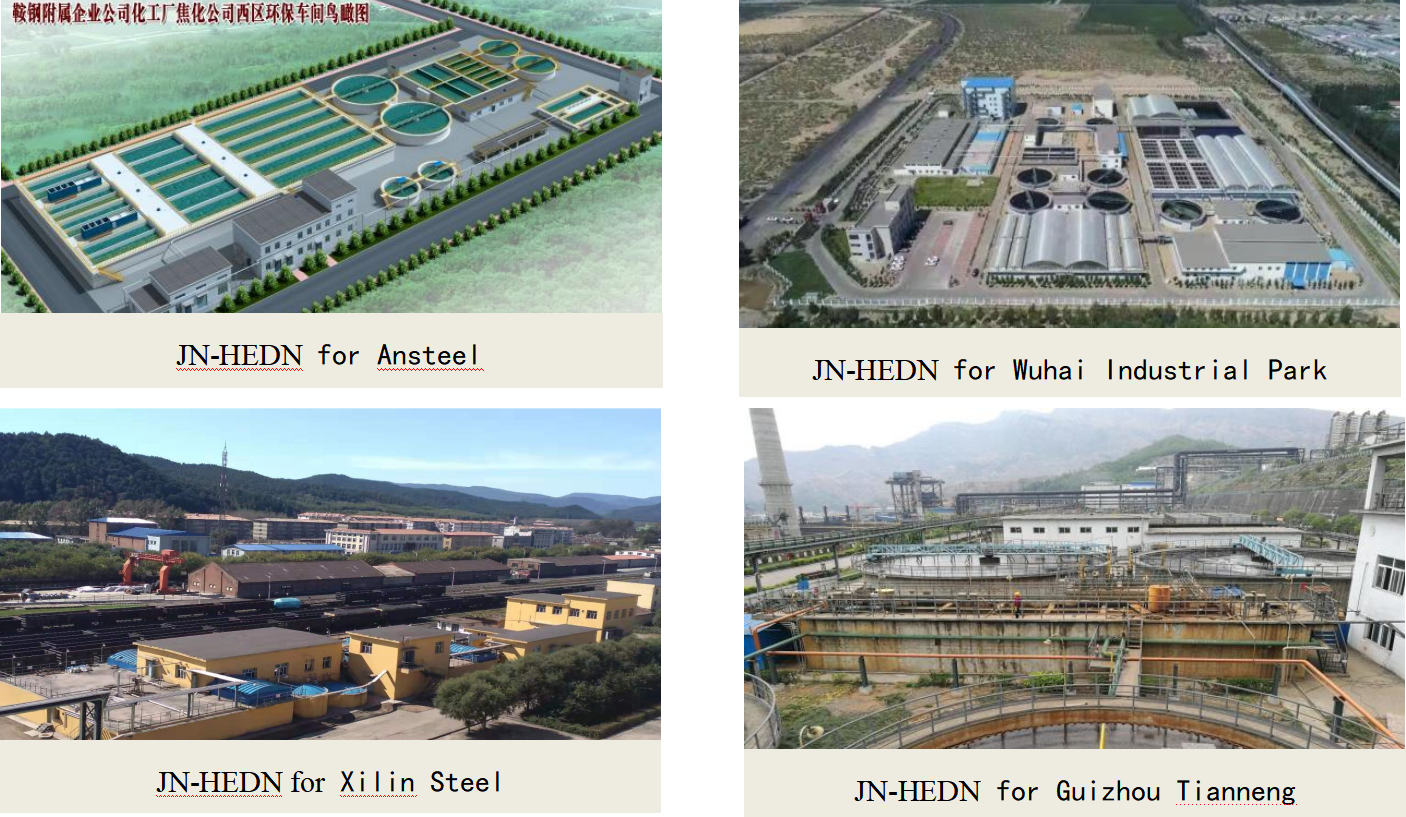

(1)High Efficiency Denitrification (JN-HEDN)

Application: It is applicable for the project without reusing demand and with bio-treated water to be discharged out or to be used for coke wet quenching, coal washing and slag granulating.

Introduction: Two-stage A/O process with particularly designed tank and passage structure and with microbial nutrients added for higher capacities of biological denitrification, dephenolization, and decyanation. This technology effectively improves the impact resistance and stability of the biochemical system, reduces the total nitrogen concentration in the effluent, and fundamentally solves the problem of excessive COD and NH3-N content for coke quenching water.

Process:

Features:

①Capable of more effective removing organics of phenol and cyanide as well as ammonia compounds from the wastewater;

②High volume loading, high efficiency of denitrification and high impact resistance;

③NH3-N content in effluent lower than 1mg/L, TN lower than 20mg/L

Water quality before & after treatment:

(2)High Efficiency Advanced Treatment & Reusing (JN-HEATR)

Application: It is applicable for the project with product water to be reused and membrane concentrate to be used for coke wet quenching, coal washing and slag granulating.

Introduction: The catalytic oxidation combines with activated carbon adsorption to effectively remove pollutants,lower the risk of fouling in the membranes, and extend the service life of the membrane.The membrane concentrate is reused after treatment, which solves the problem of excessive effluent discharge per ton of coke production and improves recovery rate of water resources.

Process:

Technical features:

①Recovery rate up to over 75%

②High level of automation and stable operation

③Low frequency of membrane cleaning and long service life of membrane

④Product water quality in compliance with national standard Code for Design of Industrial Recirculating Cooling Water Treatment (GB/T50050-2017)

Water quality before & after treatment:

(3)High Efficiency Reusing & Zero-Liquid Discharge(JN-HERZD)

Application: It is applicable for the project which has requirements for reusing product water, zero-liquid discharge & salt separation from membrane concentrate.

Introduction: The technology is characterized by combination of nano-filtration (NF) with evaporation & crystallization,highly-effective separation of Na2SO4 and NaCl by multi-stage of NF, and use of concentration membrane with high multiplying power to reduce the size of evaporator.It comes with full recovery of coking wastewater and salable secondary industrial salts to achieve zero-liquid discharge of any wastewater and reusing it as resource.

Process:

Technical features:

①High stability in operation, with multi-stage salt separation for higher production and quality of Na2SO4 & NaCl and less secondary salts

②Full recovery of RO permeated water and evaporation condensate

③Product water quality in line with national standard Code for Design of Industrial Recirculating Cooling Water Treatment (GB/T50050-2017)

④Na2SO4 quality up to the standard of product grade I of Class A in standard Coal Chemical Industry By-product Industrial Sodium Sulfate (T/CCT 001-2019)

⑤NaCl quality up to the standard of product grade I of dry salt in standard Coal Chemical Industry By-product Industrial Sodium Chloride(T/CCT 002-2019)

Water quality before & after treatment:

Case 1

Project: Wastewater Reuse Treatment Upgrading for Panzhihua Iron& Steel

Location: Xichang City, Sichuan Province, China

Model: Build-Operate-Transfer (BOT)

Commissioning date: December 24, 2020

Operation period: 10 years

Description:

The “JN-HEDN Efficient Denitrification Technology for Coking Wastewater” and “JN-HEATR Advanced Treatment and Reuse Technology for Coking Wastewater” were applied to the upgrading of this project. The treated permeate from the reverse osmosis (RO) system meets the requirements of Table 6.1.3 in GB/T 50050-2017 – Code for design of industrial circulating cooling water treatment. The brine effluent meets the indirect discharge standards specified in Table 1 of GB 16171-2012 – Emission standard of pollutants for coking chemical industry, achieving cascade utilization and reuse of wastewater.

Features:

The project integrates biological denitrification, Fenton catalytic oxidation, and activated carbon adsorption technologies to enhance pollutant removal efficiency, reduce membrane fouling risks, and extend membrane service life. The ultra-filtration (UF) membranes have been operating stably for four years, and the reverse osmosis (RO) membranes were replaced after three years of stable operation.

Project photos:

Case 2

Project: Hebei Xuyang Coking Concentrated Brine Zero Discharge Project

Location: Dingzhou City, Hebei Province, China

Model: Build-Operate-Transfer (BOT)

Commissioning date: December 24, 2020

Operation period: 5 years

Description:

The “JN-HERZD Efficient Reuse and Zero Discharge Technology for Coking Wastewater” was applied to treat the brine from coking processes. The produced sodium sulfate meets the quality standard for Grade A First-Class Products specified in T/CCT 001-2019 - Coal chemical industry - By-product industrial sodium sulfate, while the sodium chloride product can meet the Primary Industrial-Grade Dried Salt standard specified in T/CCT 002-2019 - Coal chemical industry - By-product industrial sodium chloride. This technology enables all wastewater into reusable resources.

Features:

By coupling two-stage nano-filtration with MVR evaporation crystallization and applying two-stage H.P. reverse osmosis, downsizing the MVR evaporator, saving both CAPEX and OPEX. achieving zero liquid discharge and full resource recovery of all plant wastewater.

Project photos:

Typical Reference List for Wastewater Treatment by ACRE (1999-2025)

|

No. |

Project |

Treatment capacity (m3/d) |

Processes |

Signed in |

Commissioned in |

Contract mode |

|

1 |

Anshan No.2 Wastewater Treatment Plant |

100,000 |

Screening + Grit Removal Chamber + SBR + Flocculation + Filtration + Disinfection |

1999 |

2,000 |

E |

|

2 |

Anshan No.2 Wastewater Treatment Plant (Ph-2) |

200,000 |

Screening + Grit Removal Chamber + A/O + Flocculation + Disinfection |

2000 |

2001 |

E |

|

3 |

Fushun Special Steel Wastewater Treatment Project |

45,000 |

Coarse Screen + Flow Equalization + Fine Screen + Sedimentation + DAF + Filtration |

2002 |

2002 |

E |

|

4 |

Haicheng Wastewater Treatment Plant |

50,000 |

Screening+ Grit Removal Chamber+ A/O+ Flocculation + Disinfection |

2001 |

2003 |

E |

|

5 |

Phenol-Cyanide Wastewater Treatment Station Project for Ansteel Yingkou Bayuquan Coking Project (EPC) |

5,760 |

Two-stage Deoiling→A/A/O→Coagulation & Sedimentation→Quenching Water Reuse & Discharge |

2007 |

2009 |

EPC |

|

6 |

Wastewater Treatment Plant for 3.3M t/a Coking Project (Phases 3 & 4) of Zhangjiagang Hongfa |

7,200 |

Two-stage Deoiling→A/A/O→Fenton Oxidation→Coagulation & Sedimentation→BAF→Quenching Water Reuse & Discharge |

2007 |

2009 |

EPC |

|

7 |

Phenol-cyanide-containing Wastewater Treatment Plant for Lingyuan Iron & Steel of Ansteel |

3,600 |

Two-stage Deoiling→A/A/O→Coagulation & Sedimentation→Quenching Water Reuse & Discharge |

2008 |

2010 |

EPC |

|

8 |

Wastewater Treatment Plant (Phase II) of Tangshan Jiahua |

4,800 |

Two-stage Deoiling→A/A/O→Coagulation and Sedimentation→Quenching Water Reuse / Discharge |

2008 |

2011 |

EPC |

|

9 |

Wastewater Treatment Plant for Gas Project Phase I (EPC) of Guizhou Huaneng |

3,600 |

Two-stage Deoiling→A/A/O→Fenton Oxidation→Coagulation & Sedimentation→Quenching Water Reuse & Discharge |

2009 |

2011 |

EPC |

|

10 |

Wastewater Treatment Plant of Wuxi Coking Plant Recolation Project |

2,400 |

Two-stage Deoiling→A/A/O→A/O Fenton Oxidation→Coagulation & Sedimentation→Quenching Water Reuse & Discharge |

2009 |

2012 |

EPC |

|

11 |

Wastewater Treatment Plant of Wuhu Xinxing |

2,400 |

Two-stage Deoiling→A/A/O→A/O Fenton Oxidation→Coagulation & Sedimentation→Quenching Water Reuse & Discharge |

2010 |

2012 |

EPC |

|

12 |

Coking Wastewater Treatment Project of Ansteel Coking Plant Upgrading Project (Ph-4, EPC) |

3,600 |

Two-stage Deoiling→A/A/O→A/O Fenton Oxidation→Coagulation & Sedimentation→Quenching Water Reuse & Discharge |

2011 |

2013 |

EPC |

|

13 |

Wastewater Treatment Plant of Xinjiang Bayi Steel Works (EPC) |

2,400 |

2nd Deoiling→A/O→High-efficiency Clarification →Advanced Treatment →Reuse through Dual Membrane |

2012 |

2014 |

EPC |

|

14 |

Wastewater Treatment Plant of Xinjiang Zhogntai (Baicheng County) |

3,840 |

Two-stage Deoiling→A/A/O→Coagulation & Sedimentation→Advanced Treatment→Reuse through Dual Membrane |

2013 |

2020 |

EPC |

|

15 |

Phenol-cyanide-containing Wastewater Treatment Project of Lianfeng Iron & Steel (Zhangjiagang)

|

8,400 |

Two-stage Deoiling→A/O→Coagulation & Sedimentation→Fenton Oxidation→Advanced Treatment→Reuse through Dual Membrane |

2014 |

On hold |

E |

|

16 |

Coking Wastewater Treatment Plant of Qingdao Iron And Steel Relocation Project |

8,400 |

Two-stage Deoiling→A/A/O→Coagulation & Sedimentation→Advanced Treatment→Reuse through Dual Membrane |

2014 |

On hold |

E |

|

17 |

Phenol-cyanide-containing Wastewater Treatment Plant Project of Huaibei Mining (Ph-2, EPC) |

9,600 |

Two-stage Deoiling→A/O→Coagulation & Sedimentation→Advanced Treatment→Reuse through Dual Membrane |

2014 |

2016 |

EPC |

|

18 |

10,000T Wastewater Treatment and Reclaimed Water Reuse Project of Wuhai |

10,000 |

Two-stage Deoiling+A/O/A/O+Coagulation & Sedimentation+Activated Carbon Adsorption+Reuse through Dual Membrane |

2015 |

2017 |

EPC |

|

19 |

Wastewater Treatment Project of Shandong Rizhao |

4,000 |

Deoiling+1st Sedimentation+A/O/A/O+Biological Fluidized Bed+Coagulation & Sedimentation+Ozone Catalytic & Oxidation+Reuse through Dual Membrane |

2016 |

2017 |

EPC |

|

20 |

Phenol-cyanide-containing Wastewater Treatment Plant of Gansu Honghui 10M t/a Coal Cascade Utilization Project (Ph-1) |

3,600 |

Two-stage A/O +Ozone Catalytic & Oxidation+Dual-membrane +Evaporation & Crystallization (MVR) |

2016 |

2017 |

EPC |

|

21 |

Leachate Treatment System for Solid Waste Incineration Power Plant of Shenyang Laohuchong |

1,000 |

Pretreatment+Equalization+Anaerobic Reactor +Degassing+Sedimentation+Pre-Aeration +Two-stage A/O+UF+NF+RO+DTRO Permeate Reuse & Concentrated Water Recirculation |

2016 |

2019-11 |

EPC |

|

22 |

Wastewater Treatment Plant of Xilin Iron & Steel |

1,200 |

Pretreatment+Deoiling+Equalization+Anaerobic Tank+Anaerobic Tank+Aerobic Tank+Sedimentation+Two-stage Anaerobic tank +Advanced Oxidation+Sedimentation |

2017 |

2018 |

EPC |

|

23 |

Coking Wastewater Treatment System in Kuantan, Malaysia |

1,600 |

Pretreatment+Deoiling+Equalization+Anaerobic Tank+Aerobic Tank+Sedimentation+Two-stage Anaerobic Tank +Two-stage Aerobic Tank+Sedimentation+Advanced Oxidation+Biological Fluidized Bed+Sedimentation |

2017 |

2019 |

E |

|

24 |

Coking Wastewater Advanced Treatment and Reclaimed Water Reuse of Xinyue Coking Plant, HBIS |

2,880 |

Two-stage Deoiling+A/A/O+Coagulation & Sedimentation+Ozone Catalytic & Oxidation+MBR+Activated Carbon +Reuse through Dual Membrane |

2018 |

2019-4 |

BOT |

|

25 |

Wastewater Advanced Treatment and Reuse Project of Baoshan Company and Meishan Branch |

Baoshan:24m3/h Meishan:200 m3/h |

RO Concentrated Brine of Baoshan: Multi-stage UF+NF+RO Meishan: Biochemical Effluent+Activated Carbon Adsorption & Regeneration +UF+RO |

2018 |

2019 |

E |

|

26 |

Wastewater Treatment Plant Upgrading of Shanxi Hongda |

1,200 |

Upgrading of Existing Biochemical Treatment System |

2018 |

On hold |

E |

|

27 |

Wastewater Upgrading Project of Guizhou Tianneng |

3,600 |

Deoiling+1st Sedimentation+A/A/O+Fenton+Activated Carbon Adsorption+Reuse through Dual Membrane |

2018 |

2019-4 |

EPC |

|

28 |

Phenol-cyanide-containing Wastewater Upgrading Project of Xichang Panjiang |

4,000 |

Deoiling+1st Sedimentation+ O/A/O+Fenton+Activated Carbon Adsorption+Reuse through Dual Membrane |

2019 |

2020-7 |

BOT |

|

29 |

Wastewater Upgrading Project of Shougang Shuicheng Iron & Steel |

2,000 |

Deoiling+1st Sedimentation+ O/A/O+Electromagnetic Catalytic Oxidation |

2019 |

2020-12 |

E |

|

30 |

Coking Wastewater Treatment and Reuse Project of Henan Jinma |

4,500 |

Deoiling+1st Sedimentation+ O/A/O+Biological Fluidized Bed+Activated Carbon Adsorption & Reuse through Dual Membrane+Evaporation & Crystallization |

2019 |

2021 |

E |

|

31 |

1.3M t/a Coking Project (Ph-2) of Inner Mongolia Hengkün |

3,360 |

Deoiling Tank→Flotation Equipment→Equalization Tank →Anaerobic Tank→First-stage Anaerobic Tank→First-stage Aerobic Tank→Two-stage Anaerobic Tank→Two-stage Aerobic Tank→Biological Fluidized Bed→Coagulation & Sedimentation→Softening→Filtration→Ultrafiltration→Nanofiltration→Reverse Osmosis→Evaporation & Crystallization Odor Treatment: Tank Sealing→Odor Collection→Centrifugal Fan→Biological Deodorization Unit→Exhaust Stack →Discharge |

2021 |

2022 |

EPC |

|

32 |

Concentrated Water Zero Discharge & Advanced Treatment Project of Hebei Risun Energy Co., Ltd.

|

1,440 (Concentrated Brine) |

Concentrated Brine→High Density Sedimentation Tank→Multi-media Filter→Ultra filtration→Resin Softening→Nano filtration→Reverse Osmosis→COD Separation Membrane→Evaporation & Crystallization Unit |

2021 |

2022 |

BOT |

|

33 |

Biochemical Engineering for Coking Wastewater Treatment Optimization Project of Xinjiang Guanghui |

7,700 |

Deoiling by Gravity→Equalization Tank 1→Air Floatation Deoiling→Pre-Aeration →1st Sedimentation Tank→1st Anaerobic Tank→1st Aerobic Tank→2nd Sedimentation Tank→2nd Anaerobic Tank→2nd Aerobic Tank→3rd Sedimentation Tank→Coagulation Reaction→High-efficiency Sedimentation→Clean Water Tank |

2021 |

2022 |

E |

|

34 |

Wastewater Treatment for 2.48M t/a Coking Project of Tangshan Tianshun |

4,800 |

Deoiling by Gravity→Equalization Tank 1→Air Flotation Deoiling→Pre-Aeration →1st Sedimentation Tank→1st Anaerobic Tank→1st Aerobic Tank→2nd Sedimentation Tank→2nd Anaerobic Tank→2nd Aerobic Tank→3rd Sedimentation Tank→Coagulation Reaction→High-efficiency Sedimentation→Clean Water Tank |

2021 |

2022 |

E |

|

35 |

Concentrated Brine Upgrading Project (EPC) of Hebei Huafeng |

2,880 (Concentrated Brine) |

Concentrated Brine→High Density Sedimentation Tank→Multi-media Filter→Ultra filtration→Resin Softening→Nano filtration→Reverse Osmosis→COD Separation Membrane→Evaporation & Crystallization Unit |

2022 |

2023 |

EPC |

|

36 |

Biochemical Treatment Project (EPC) of Xinjiang Xuantai |

1,872 |

Deoiling-Equalization-AO-2nd Sedimentation-Fluidized Bed-Coagulation & Sedimentation-Multi-media Filter-Ozone |

2022 |

2023 |

EPC |

|

37 |

2M t/a Coking Plant Upgrading Project of ChinaCoal Jiuxin (Lingshi County)

|

7,200 |

Biochemical Effluent-Activated Carbon Adsorption-High Density Sedimentation Tank-Multi-media Filtration-Ultra filtration-Reverse Osmosis Reverse Osmosis Concentrated Water-Concentrated Water HD Sedimentation Tank-Multi-media Filtration-Resin Softening-Decarbonator-HERO HERO Concentrated Water-Falling Film Evaporation & Crystallization

|

2023 |

2024 |

EPC |

|

38 |

Relocation and Upgrading Project of Dazhou Iron & Steel Coking Plant

|

Biochemical: 1,920 Reuse: 3,840 |

Deoiling-Flotation-Anaerobic Tank-Aerobic Tank-Anaerobic Tank-Aerobic (A/O-A/O)-Adsorption Reaction-Coagulation and Sedimentation Biochemical Effluent-Softening & Clarification-Multi-media Filter-Ultra filtration-Reverse Osmosis Reverse Osmosis Concentrated Water-Fenton Oxidation Treatment |

2023 |

2024 |

EPC |

|

39 |

Wastewater Treatment Plant of Yunnan Xianfu Iron & Steel |

Biochemical: 1,920 Reuse: 3,840 |

Deoiling+1st Sedimentation+ O/A/O+Coagulation & Adsorption+Reuse through Dual Membrane |

2025 |

2026 (Estimated) |

EP |

|

40 |

Wastewater Treatment Plant of Shuicheng Iron & Steel (EPC+O) |

Biochemical: 2,400 |

Deoiling+1st Sedimentation+ O/A/O+Electromagnetic Catalytic Oxidation |

2025 |

2026 (Estimated) |

EPC+O |

|

41 |

Coking Equipment Upgrading Project of Henan Tianrui |

Biochemical: 7,200 Reuse: 14,400

|

Deoiling Tank→Flotation Equipment→Equalization Tank →First-stage Anaerobic Tank→First-stage Aerobic Tank→Two-stage Anaerobic Tank→Two-stage Aerobic Tank→Coagulation, Adsorption and Sedimentation→Softening→Filtration→Ultra filtration→Nanofiltration→Reverse Osmosis→Evaporation & Crystallization Odor Treatment: Tank Sealing→Odor Collection→Centrifugal Fan→Biological Deodorization Unit→Exhaust Stack →Discharge |

2025 |

2027 (Estimated) |

E |

|

42 |

2M t/a Coking Project (EPC) of Guizhou Shuicheng Iron & Steel

|

Biochemical: 2,880 Reuse: 7,200 |

Deoiling Tank→Flotation Equipment→Equalization Tank →First-stage Anaerobic Tank→First-stage Aerobic Tank→Two-stage Anaerobic Tank→Two-stage Aerobic Tank→Coagulation, Adsorption and Sedimentation→Softening→Filtration→ Ultra filtration→Nano filtration→Reverse Osmosis→Evaporation & Crystallization Odor Treatment: Tank Sealing→Odor Collection→Centrifugal Fan→Biological Deodorization Unit→Exhaust Stack →Discharge |

2024 |

2025 |

EPC |

|

43 |

Fengmei Coking Wastewater Zero Liquid Discharge (ZLD) Project |

3,600 |

Softening→Filtration→Ultra filtration→Nano filtration→Reverse Osmosis→Evaporation & Crystallization |

2025 |

2027 (Estimated) |

E |