Emission Control Technologies

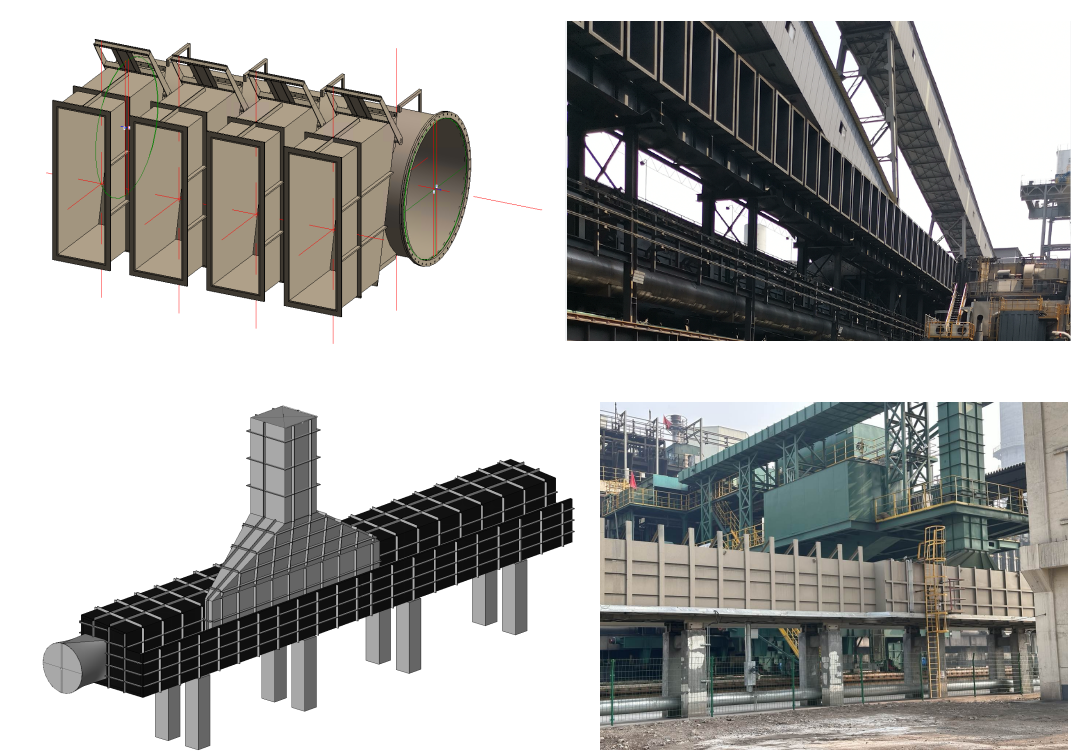

· Smokeless charging systems integrated with smokeless charging cars for top-charging coke ovens

· Charging emission collection systems paired with dedusting systems for top-charging coke ovens

· Charging emission transfer solutions for stamp-charging coke ovens

· Oven door emission capture and cleaning systems for both top-charging and stamp-charging coke ovens

· Coke pushing emission collection and dedusting systems for pushing operations

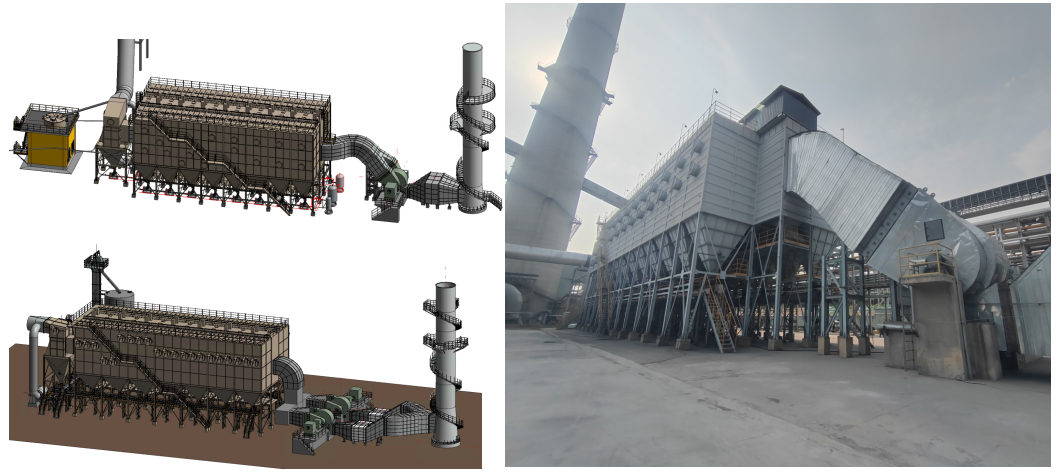

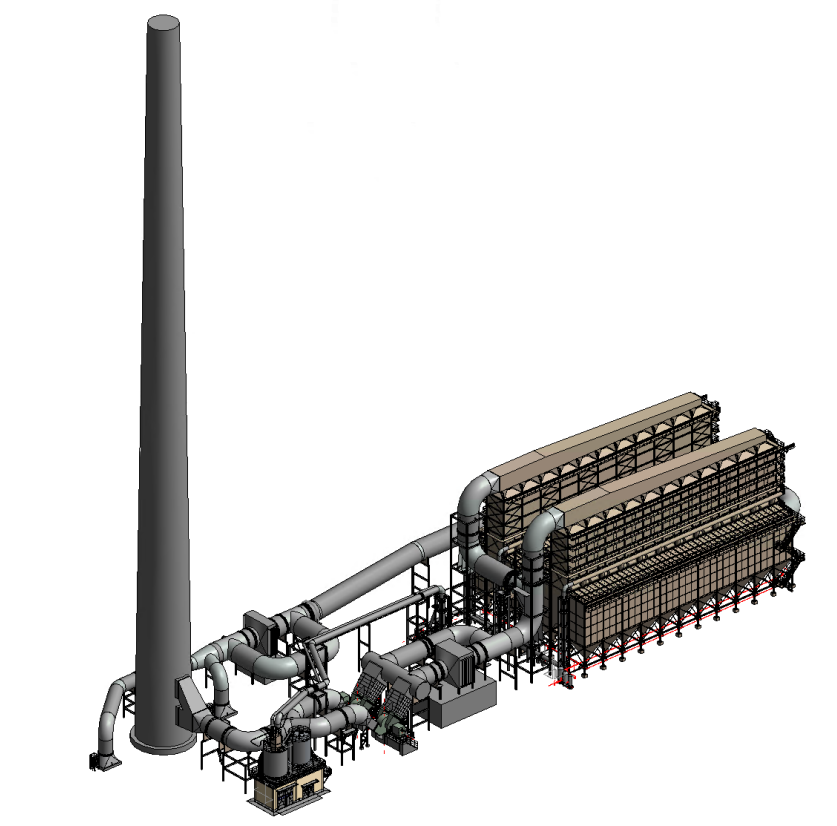

2. Flue Gas De-SOx and De-NOx Solutions

ACRE’s advanced coke oven flue gas De-NOx and De-SOx technologies are designed to meet the world’s most stringent environmental standards:

De-SOx Technologies:

· Ca-based dry De-SOx

· Na-based dry De-SOx

· Ca/Na-based SDA semi-dry De-SOx

· Ammonia desulfurization

· Wet limestone/gypsum desulfurization

De-NOx Technologies:

· Low-temperature NH₃-SCR

· High-temperature NH₃-SCR

Integrated De-NOx & De-SOx Systems:

· Na/Ca-based dry De-SOx + Dedusting + Low-temperature NH₃-SCR (+ Waste Heat Recovery)

· Na-based SDA semi-dry De-SOx + Dedusting + Low-temperature NH₃-SCR (+ Waste Heat Recovery)

· Low-temperature NH₃-SCR + Waste Heat Recovery + Ca-based SDA semi-dry De-SOx

· Low-temperature NH₃-SCR + Waste Heat Recovery + Ammonia Desulfurization / Flue Gas Heat Exchange

· Integrated active carbon-based De-NOx and De-SOx technology

3. Carbon Monoxide (CO) Removal Technology

ACRE is currently advancing CO removal technology for industrial flue gases and has successfully developed a high-performance CO removal catalyst. Industrial trials on coke oven flue gas and Coke Dry Quenching (CDQ) vent gas have confirmed the catalyst’s outstanding CO removal efficiency and operational stability.