Waste heat deep recovery (VFED) from flue gas

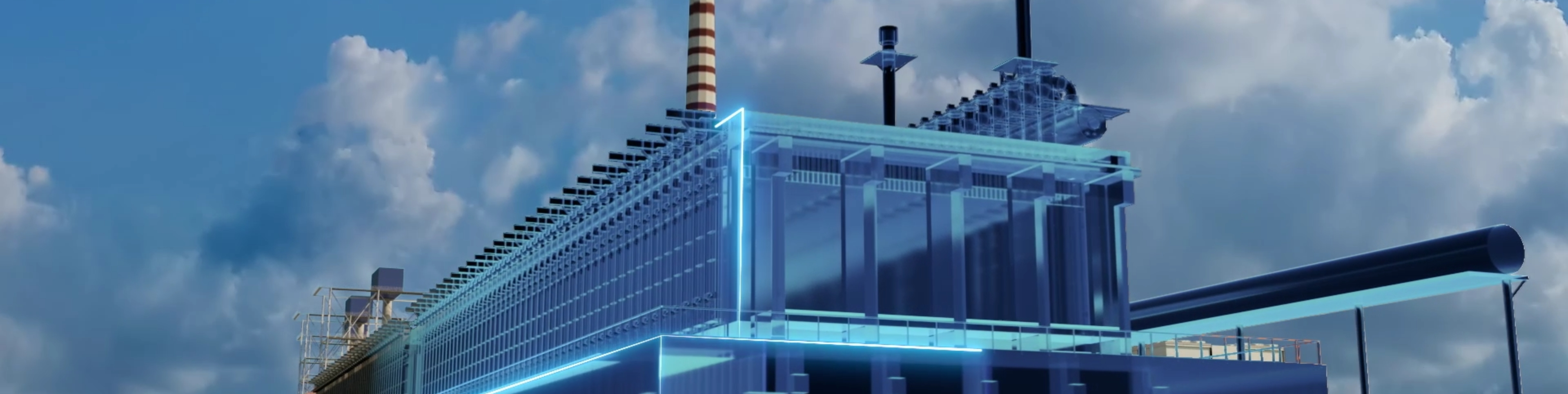

Introduction: VFED technology enhances the existing wet flue gas desulfurization system by integrating an additional VFED unit. Part of the desulfurization slurry circulates through this unit and is pumped to the top of desulfurization column for spray, reducing flue gas temperature. Furthermore, the evaporator of absorption-type heat pump system captures latent heat from steam condensation, upgrading it to hot water for external use. The condensed purified water can replenish the desulfurization slurry or serve other process needs, ensuring water balance within the system.

Advantages:

l Connectable to wet flue gas desulfurization system, with flexibility

l No modifications or additional energy consumption required for the existing desulfurization system

l Maintaining water balance within the system

l Improving desulfurization efficiency

l Recovery of the waste heat equivalent to app. 5% of coal calorific value

For a 350MW coal-fired unit, under full-load operation, the flue gas flow rate after desulfurization is app. 1.38M Nm³/h. Cooling the flue gas from 55℃ to 42℃ condenses 59.8g of water per cubic meter of flue gas and releases substantial heat, allowing for total heat recovery of 61.3MW. This represents saving 27,300 tons of coal per heating season, reducing carbon emissions by app. 80,000 tons, along with a reduction in the pollutants carried by this condensed water.