Efficient Waste Heat Recovery Technology for Coke Oven Stand Pipe

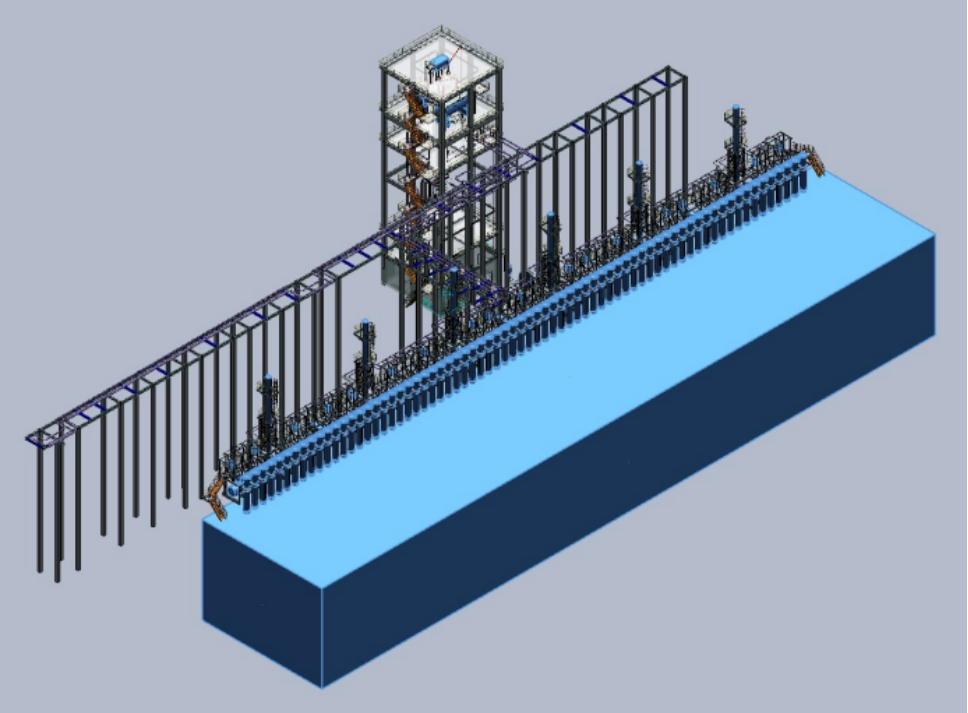

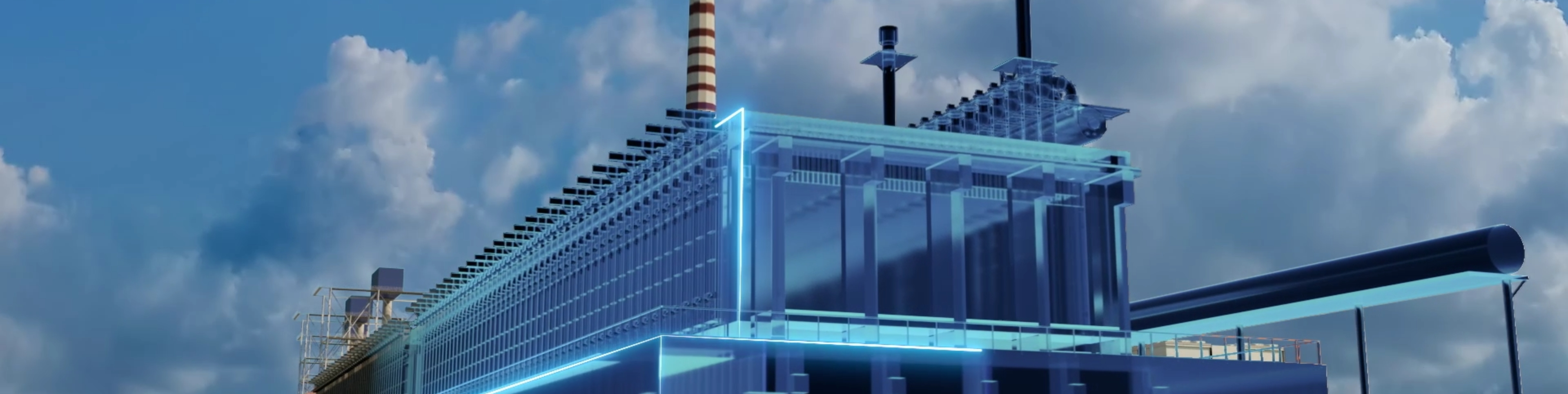

Efficient Recovery of Raw Coke Oven Gas Waste Heat

This technology recovers waste heat from raw coke oven gas at 650–750°C through standpipe heat exchangers.It produces 0.6–3.8 MPa saturated or superheated steam, achieving cascade utilization of thermal energy and significantly reducing energy consumption in the coking process.

Technical Advantages

lStable and Adjustable Steam Production

Steam production rate of approximately 80–110 kg/per ton of coke

lIntelligent Control System

Fully automatic operation, real-time monitoring, wireless temperature measurement,and protection against burning out due to interruption of water supply

lEnergy Saving and Environmental Benefits

Reduction of energy consumption by approximately 10 kgce/ton of coke

Reduction of CO2 emissions by approximately 24 kg/ton of coke

lProven Applications

Over 100 units applied worldwide