COAL & COKE HANDLING

ACRE provides customized coal handling process for various types of coke oven and coke based on the coal of different sources and qualities.

★ For pre-curshing of hard coal, the process of coal blending first, and then crushing and mixing.

★ The process of individual kind of coal crushing first and then blending.

★ Blending and crushing in groups;

★ Screening and crushing process;

★ Coal Moisture Control process(CMC);

★ Coal Briquetting;

★ Blending coke breeze into coal blend

★Intelligent coal blending system

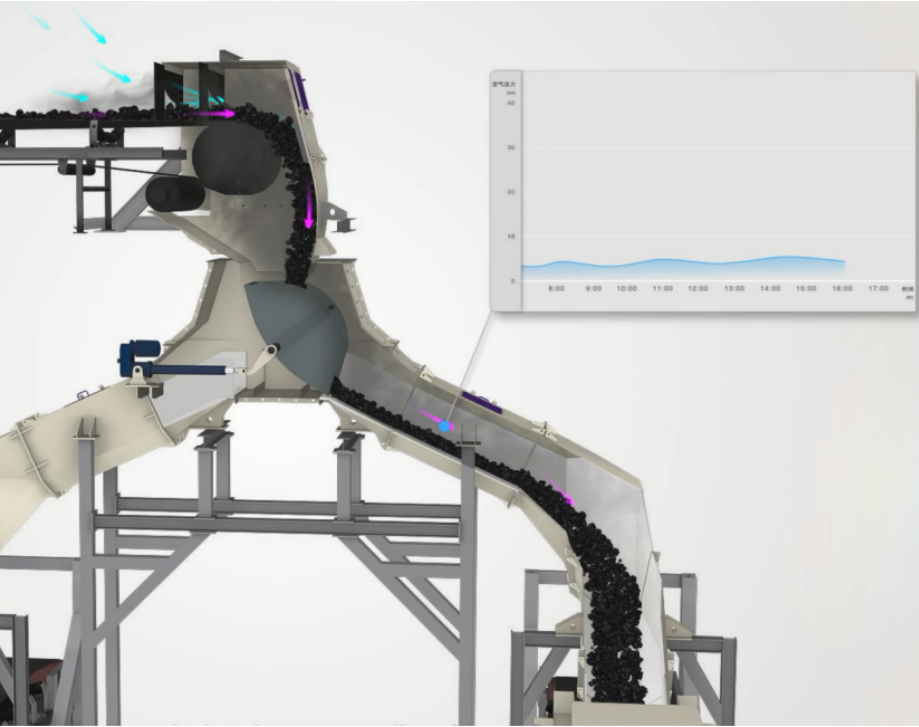

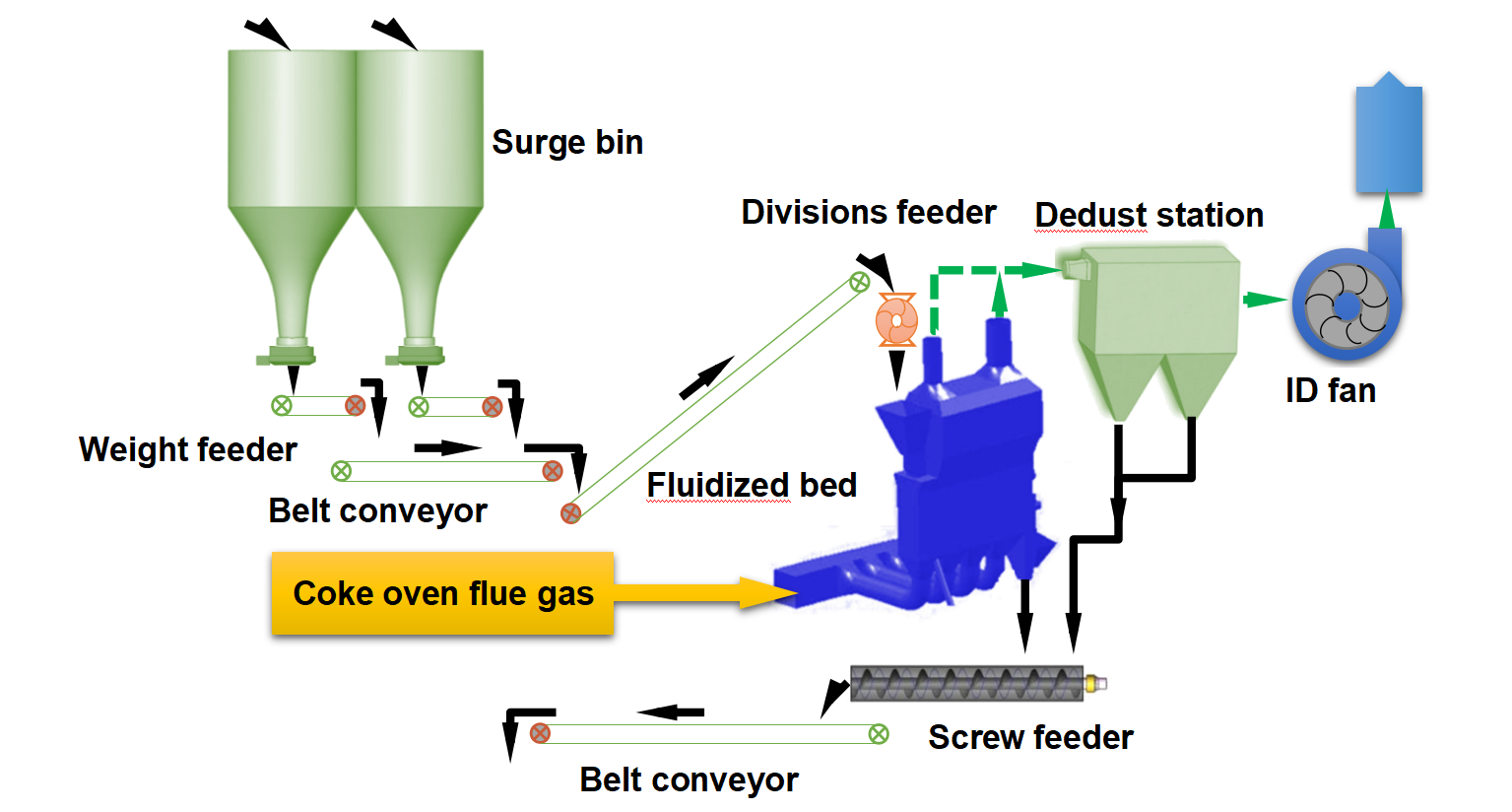

Coal Moisture Control (CMC) with Swirling-full-fluidized-bed process

With coke oven flue gas as the heating source, swirling airflow inside the equipment drives and forces the materials for sufficient heat exchange. A portion of the moisture was evaporated before the coal is charged to coke oven.

It can reduce coal water by approximately 30%, lower heat consumption during cokemaking by about 4%, increase coke oven production by roughly 5%.It also improves the cold strength (M40) of coke by about 1%, and enhances CSR by approximately 0.5-1%.

Coal briquetting

This process mixes dust and coal in a certain proportion with binders (soft pitch, tar residue, waste desulfurization liquid) to produce briquettes by the forming machine. These briquettes are then blended with the coal charge. This technology can help to reduce dust emissions, increase bulk density of the charged coal, improve coke quality, and lower raw material cost per ton of coke. With the same coal blend ratio, cold strength of coke increases by about 1-2%.Alternatively, the proportion of strong caking coal can be reduced by 10-15% while maintaining the same coke quality.The uniformity coefficient of coke particle size is improved, and the coal charge per oven is increased by approximately 5%-8%.

Incorporation of coke breeze to coal blending for cokemaking

By this technology, fine coke (<10mm) is further processed down to coke breeze of a certain size, which is then, as a leaning agent, mixed into the coal blend for cokemaking. This process can help to reduce the volatile matter of the blended coal, decrease gas generation, lower coke porosity, and increase lump size and crushing strength. The ratio of additional coke breeze can reach 4%,while the average particle size is increased by over 1mm, and the content of particles (<25mm) in full composition is reduced by 0.8-1.5%.

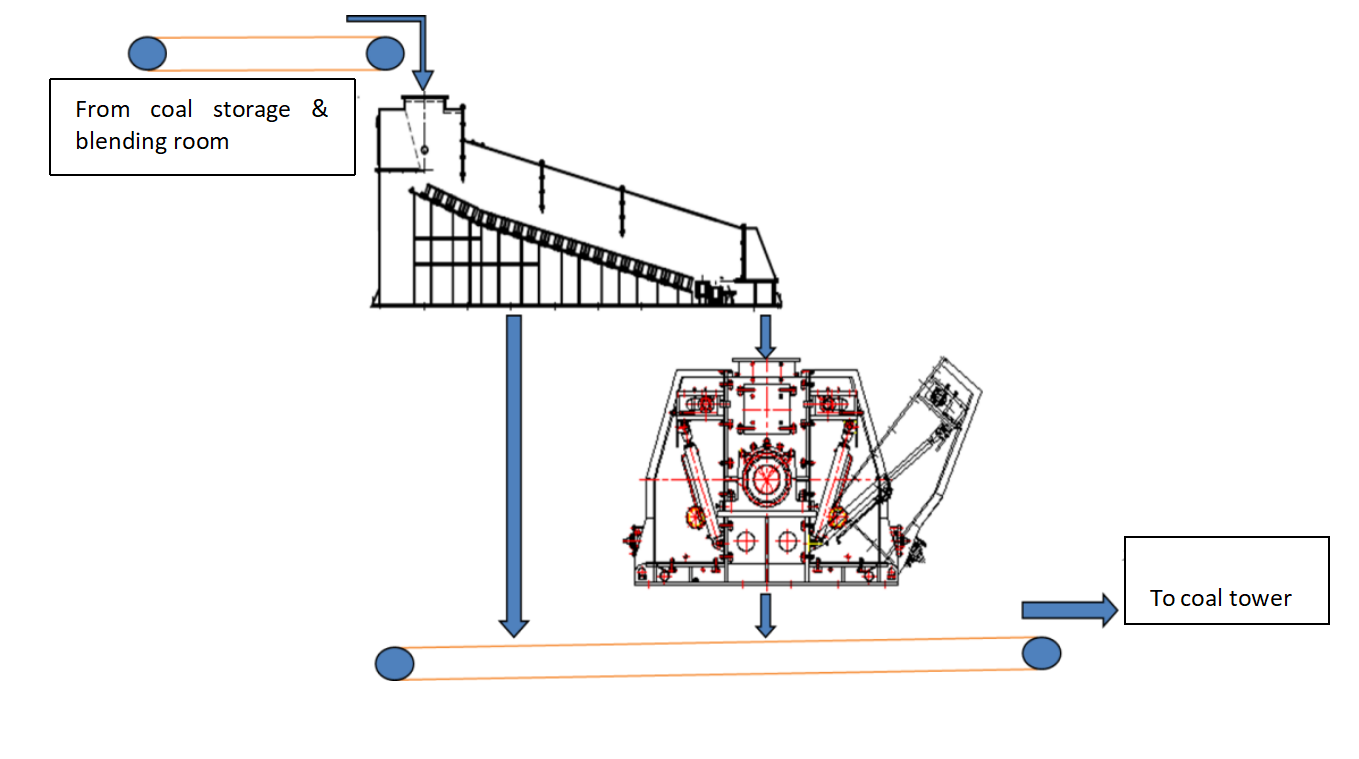

Blended coal screening & crushing technology

The crossover screen is adopted for the screening of blended coal. The oversize material (particle size >3mm) after screened is sent to the crusher, while the undersize material (particle size ≤3mm) bypasses the crusher to avoid over-crushing. This is for the purpose of energy saving, reducing consumption and operating costs, and improving coke quality. The screening efficiency for the coal size (<3mm) is over 65% while the proportion of undersize material (<3mm) is over 70%.

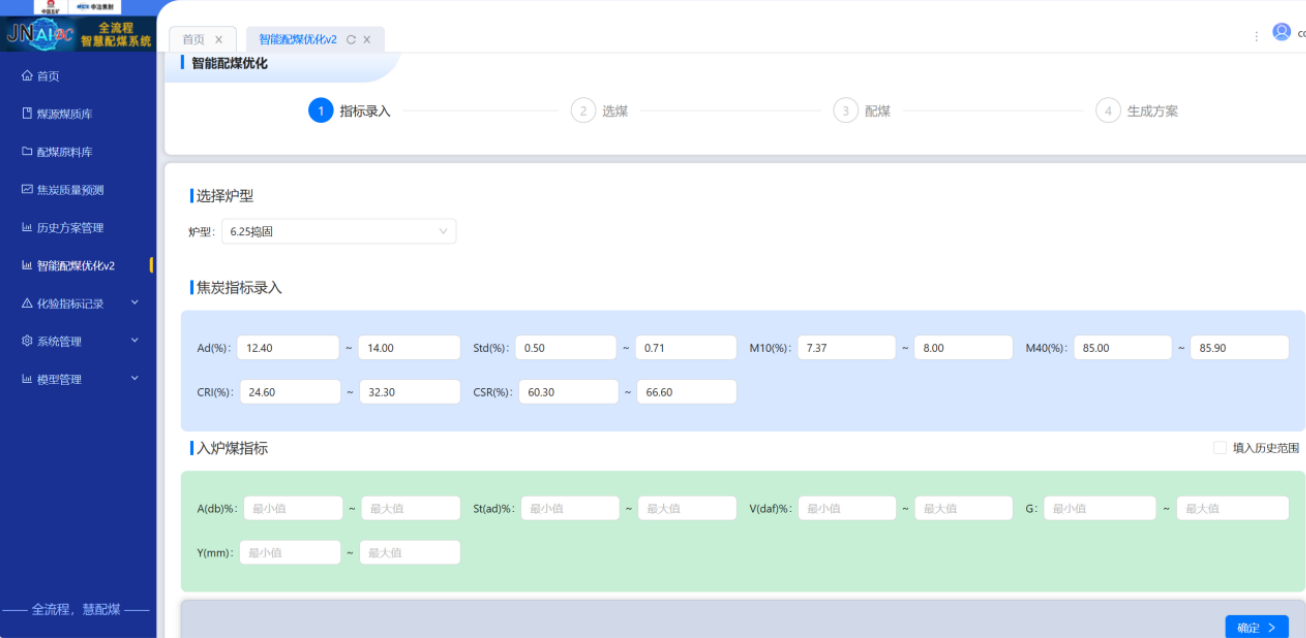

Intelligent coal blending and cokemaking system

This system is developed based on ACRE's intelligent coal blending and cokemaking model. With self-developed AI algorithms, the system is deeply applied in production. The model is capable of accurately predicting coke quality, optimizing coal blending costs, reducing raw material costs and improving production for cokemaking enterprises.The blending cost per ton of coal is reduced by approximately 5 RMB yuan.

ACRE provides coke handling process to separate coke to different sizes as per demands of endusers.

New technologies for coke handling:

Static Sealed Coke Screening Technology

By combining "non-vibrating screen box + rigid full seal + negative pressure dedusting" to significantly reduce dust and energy consumption while ensuring screening efficiency. The air leakage area of the screen box is reduced by over 80% compared to traditional vibrating screens.

Large-capacity Silo Storage for Coke

By adopting "automatic material distribution + breakage reduction inside the silo," this technology can achieve intelligent, dust-free, and enclosed storage of coke.The storage capacity per silo is 5,000-12,000 tons. The breakage rate of coke entering silo is reduced by over 50%.

Environment-friendly Coke Yard with Gantry Crane

This technology will increase coke storage capacity while reducing infrastructure investment. Coke breakage rate is lowered during handling and transfer. It can meet requirements for large-scale coke storage facilities. The coke yard features full coverage with misting device, nebulization dust suppression at discharge points, and cartridge filter for dedusting to meet environmental requirements. It saves over 35% of land area compared to the yard with arm-type stacker-reclaimer. The inclusion of vehicle-mounted movable telescopic sleeves solves the dedusting problems during stockpiling in traditional design.

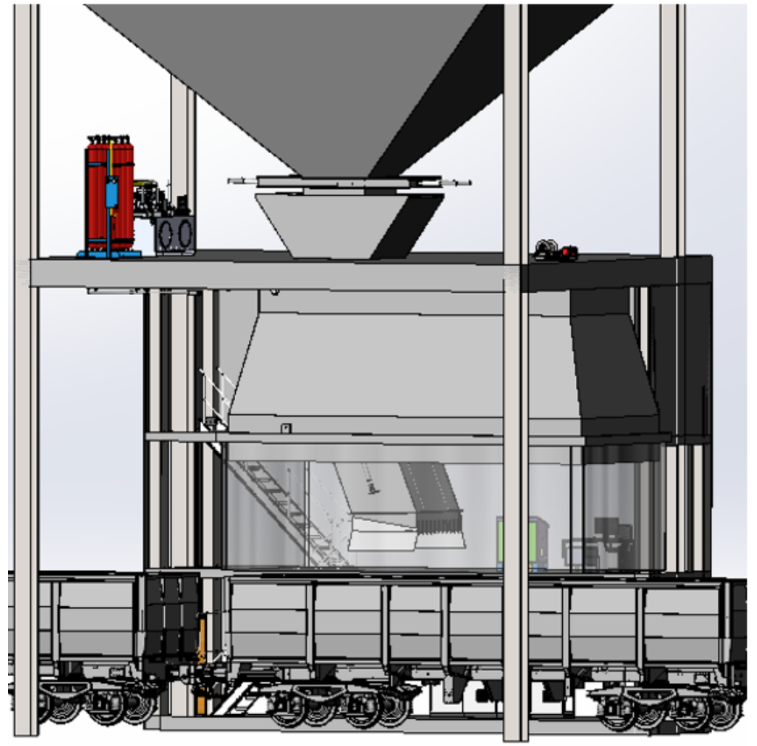

Rapid Coke Loading on Railway Wagons

This process meets the demand for rapid and quantitative coke loading of railway wagons.The loading process is automated and quantitative, with no manual work throughout. It takes only 2 minutes for coke loading per wagon.

Rapid Coke Loading on Trucks

This process meets the demand for rapid and quantitative coke loading of trucks. The loading process is automated and quantitative, with no manual work throughout. It takes only 5 minutes for coke loading per truck.

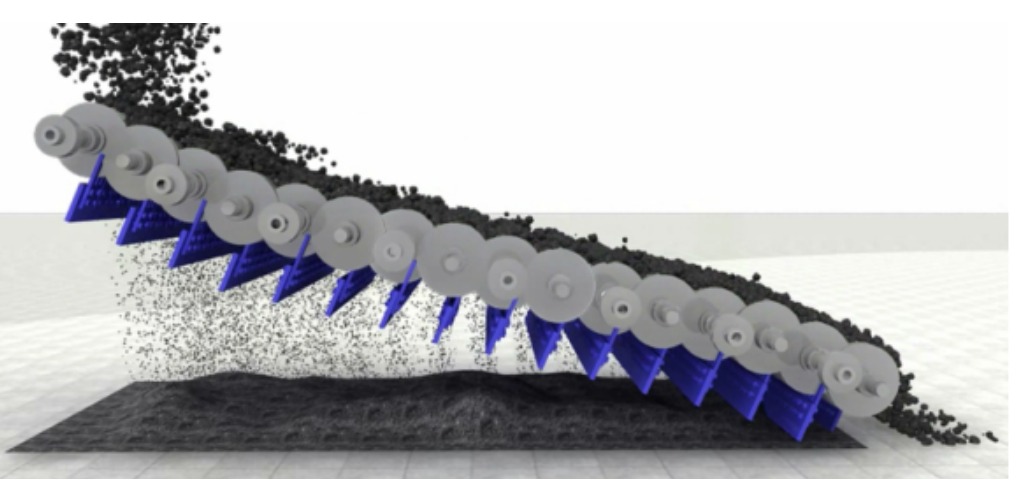

Technology of Controllable Flow for Coke Transfer

This technology is developed based on analysis and study of the characteristics of bulk materials. It adopts material flow simulation software to precisely simulate and verify the trajectories of materials flow, and optimize the material flow path. This minimizes the impact force and wear of material on the receiving area of the lower conveyor belt, fundamentally solves issues related to breakage, dust, blockage, belt misalignment during loading and maintenance. The breakage rate at transfer points is reduced by over 50%. The air volume required for dedusting is decreased by approximately 40%.