Battery heating-up

Battery heating-up refers to the operation of heating the battery from air temperature to the level of battery heating. It's an important and sophisticated process before battery commissioning. The quality of heating-up has a crucial impact on smooth operation and service life of coke oven production.

Negative pressure heating-up

The air required for negative pressure heating-up is drawn in by the chimney draft. The followings are the main features of ACRE's negative pressure heating-up technologies. First, simple heating-up device and low investment and costs. Second, when using gas fuel for heating-up, there are more options available, such as using low calorific gases like blast furnace gas. Third, automatic temperature measurement and wireless collection of oven temperature.

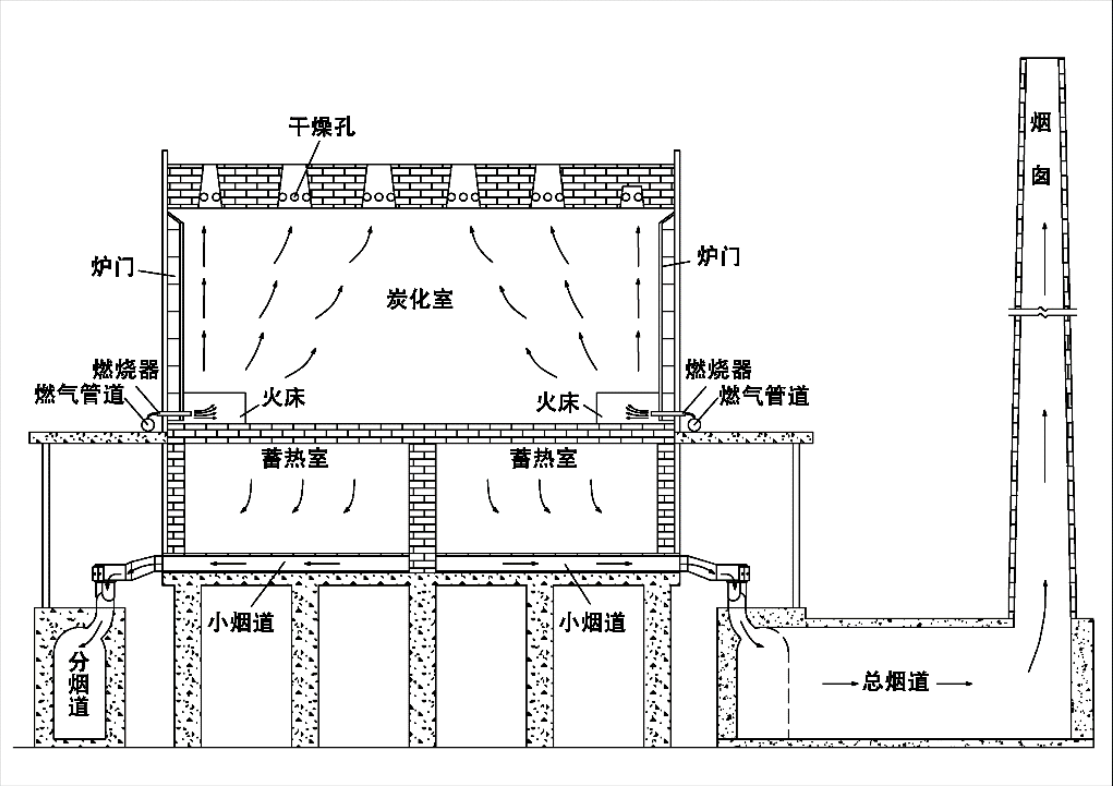

Schematic diagram of negative pressure heating-up

Negative pressure heating-up of more than 300 batteries of various types has been completed by ACRE in China, and heating-up of more than 30 batteries have been conducted abroad, in India, Japan, Indonesia, Vietnam, South Africa, Türkiye, Brazil and other countries.

Negative pressure heating-up at Pansteel plant.

Positive pressure heating-up

For positive pressure heating-up, air and hot flue gas generated after combustion are propelled by fan to maintain positive pressure in coking chamber.

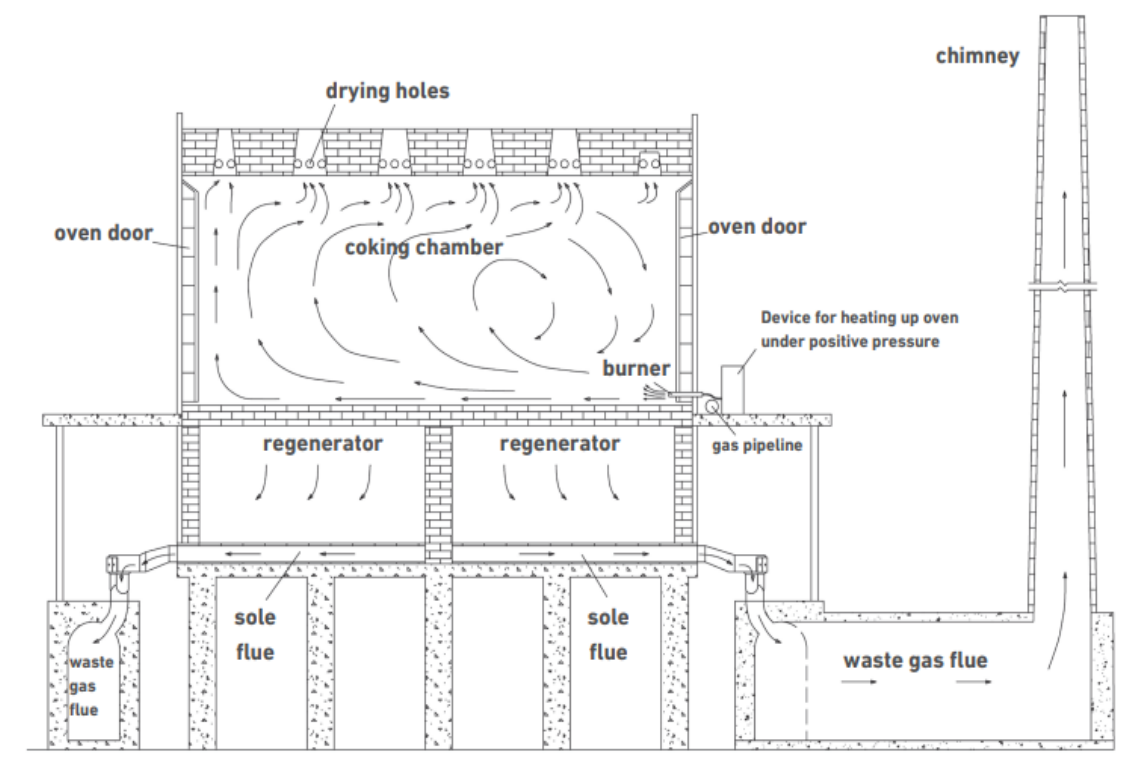

Schematic diagram of positive pressure heating-up

The main features of ACRE's positive pressure heating-up technologies are as follows:

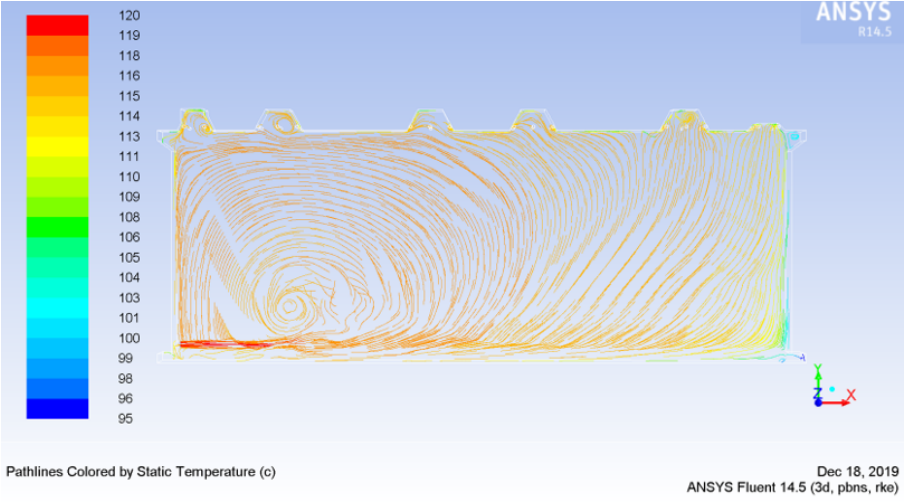

1.Better heating-up because of outstanding technological advantages. The process begins by filling the ovens with hot waste gas. Then hot gas flows evenly through drying hole to the heating wall, forming a positive pressure inside heating wall, ensuring that cold air cannot flow into the oven proper. Temperature rise is uniform throughout the battery and heating-up quality will be better.

Oven temperature distribution simulation

2.Short heating-up duration. Due to more uniform temperature rising, the heating-up time for battery from room temperature to 800 ℃ is about 55-60 days, while negative pressure heating-up usually takes about 65-70 days, which can be shortened by about 10 days.

3.Not required for building false hearth. At the early stage of heating up, the flame burns completely inside the burner. At the later stage, when the gas flow rate is high, the rigidity of the flame is effectively ensured, avoiding the flame from contacting oven wall.

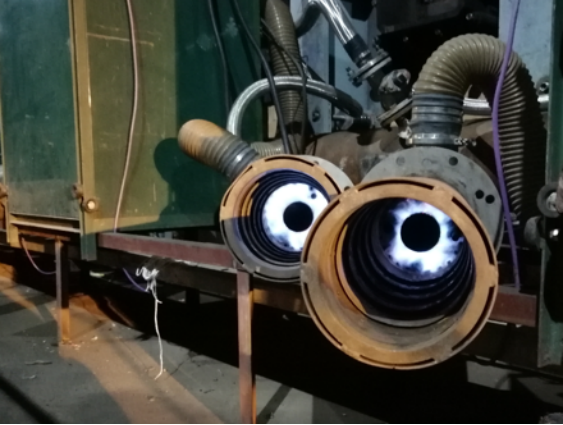

During the initial stage of heating-up, heating-up, flame burns inside the burner

Better flame rigidity at the later stage of heating-up

4.High safety. Numerous safety interlocks of the combustion system ensure a high degree of safety during heating-up.

5.High degree of automation, capable of remote control. Over 95% of operation achieves automatic and remote control, including real-time monitoring of temperature rise by using a mobile phone.

6. Automatic temperature measurement and wireless collection of oven temperature

Wireless collection of oven top temperature

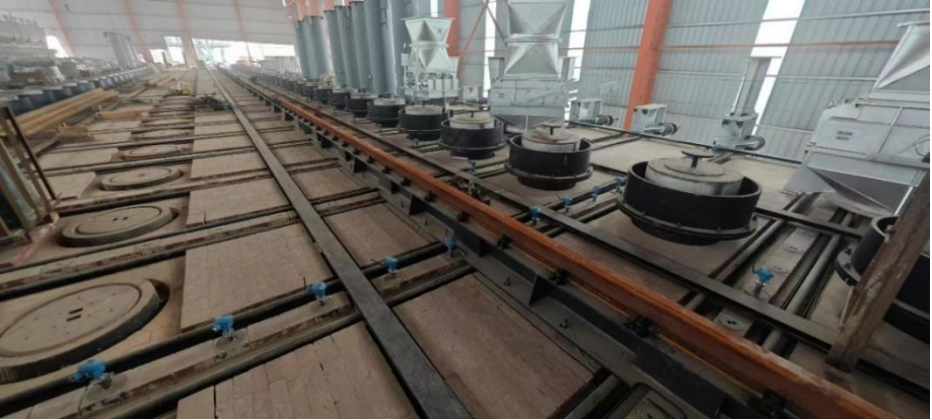

Since 2018, more than 1X00 batteries have been built with adopting ACRE’s positive pressure heating-up technologies, which have been widely recognized.

Positive pressure heating-up