Coal tar refining

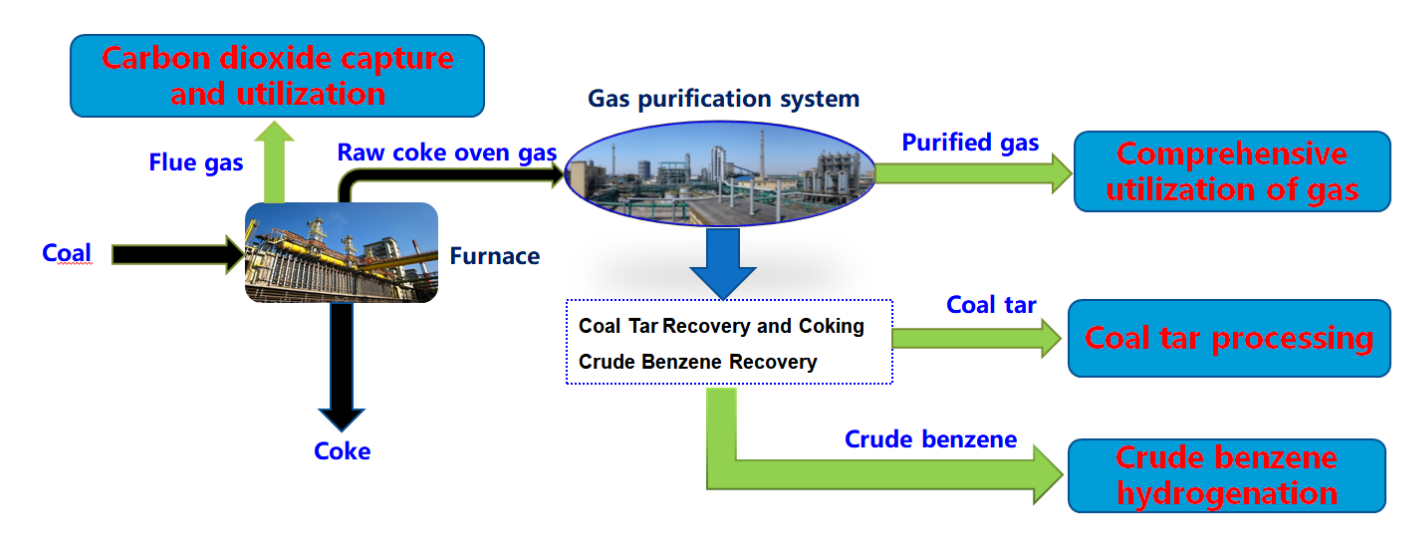

ACRE has developed an integrated industrial chain that leverages cokemaking by-products—tar, crude benzene, and gas—to produce carbon-based new feedstocks, including aromatics, alcohol ethers, and other chemical products.

High-temperature coal tar, a key by-product in coking process, plays a vital role in ACRE's business. For over 70 years, ACRE has not only executed over 90% of coal tar refining projects but has also continuously advanced new technologies and high-value-added products. Our refining facilities now handle up to 500,000 tons annually, yielding more than 40 kinds of products.

Technological Innovations:

1. Two-stage tar distillation (atmospheric and vacuum distillations)

Features: Low energy consumption, 20%–30% fuel gas saved compared with conventional atmospheric distillation.

2. Production of Industrial Naphthalene by Pressurized Distillation

Features: Low energy consumption, with 30%–40% fuel gas savings compared with atmospheric distillation; high product recovery rate: >96%.

3. Production of Refined Naphthalene, Refined Anthracene, and Refined Carbazole by Using Box Crystallizer

Features: High-purity products: refined naphthalene purity ≥99.98%; refined anthracene purity ≥96%; refined carbazole purity ≥95%.

ACRE's coal tar refining plants also employ technologies such as counter-current continuous fraction washing and dephenolization, atmospheric and vacuum distillation for producing refined phenols, high-efficiency distillation for extracting wash oil, pitch refining for manufacturing modified pitch, mesophase pitch, delayed coke, and needle coke, as well as hydro-refining of coal tar fractions to produce light oils.