Efficient Recovery of Waste Heat from Coke Oven Flue Gas

Efficient Utilization of Medium-Low Temperature Flue Gas Waste Heat

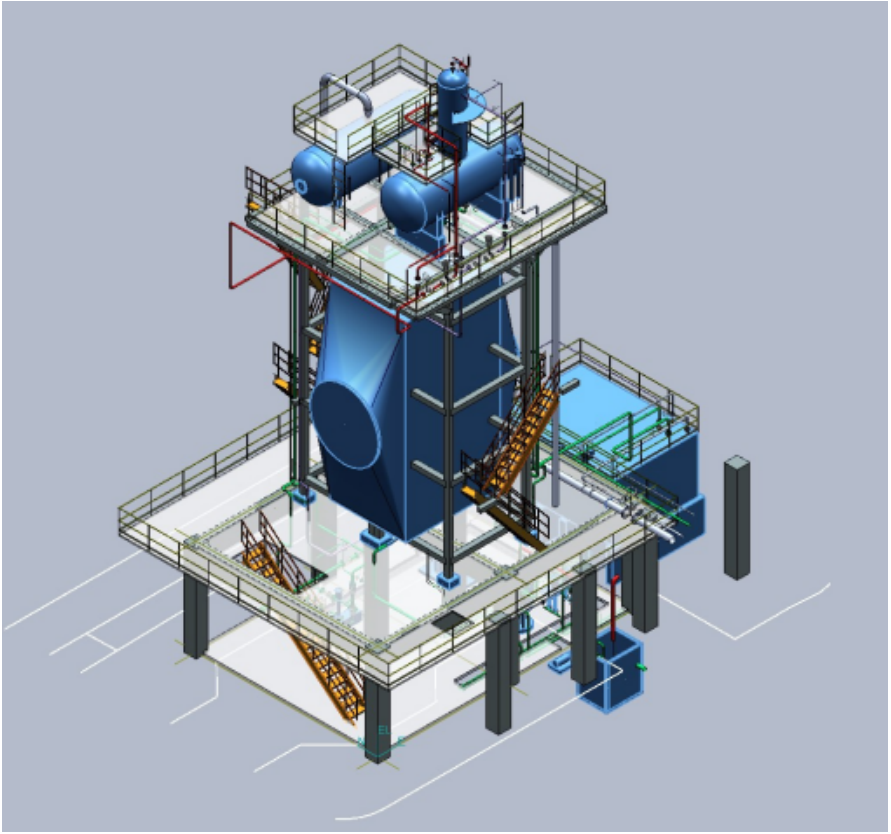

This technology focuses on recovering waste heat from coke oven flue gas at 180~300℃, producing L.P. steam or hot water.The system operates in sync with coke oven operation without interruption, offering both energy-saving and environmental benefits.

Technical Advantages

lCorrosion-Resistant Design

The finned tube-heat pipe waste heat boilers are adaptable to L.P. corrosive environments

lModular Structure

Easy installation with highly integrated system

lStable and Adjustable Steam Production

Steam production rate of approximately 50–100 kg/ton of coke

lEnergy Saving and Environmental Benefits

Reduction of energy consumption by approximately 6 kgce/ton of coke

Reduction of CO2 emissions by approximately 14 kg/ton of coke