Heat Recovery

Heat-Recovery Coke Ovens offer the following advantages:

• Non recovery

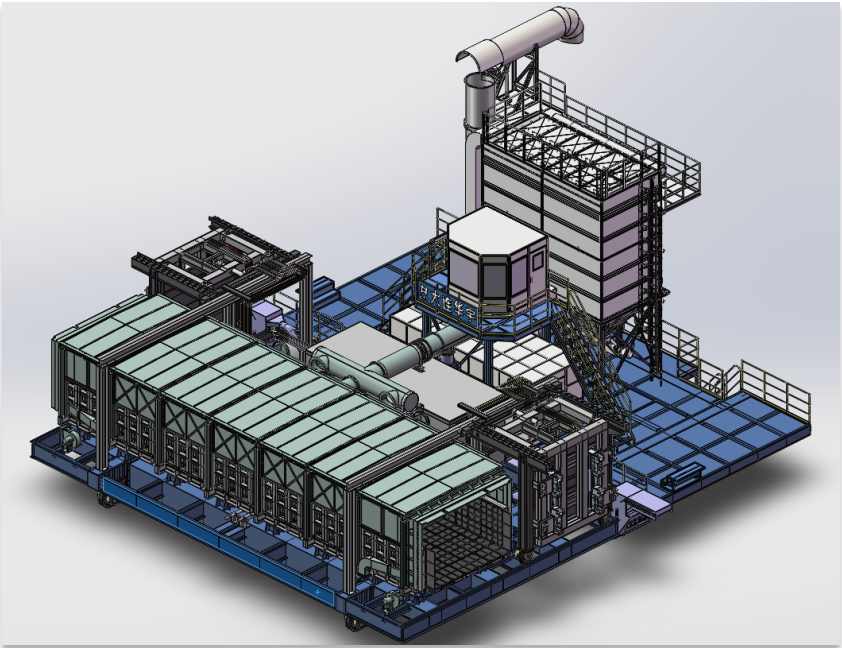

• Product: Coke and electrical power and/or steam

• Stamp-charging from pusher side

• Using more weak-caking coal to produce high-quality coke

• 3 quenching process can be chosen: Traditional quenching/Dry quenching/Low-Moisture Quenching

• Minimized emission, Negative Pressure Operation

ACRE can supply two types of heat recovery coke oven technologies:

• Stamp-charging horizontal oven type of heat recovery coke oven (Primary recommendation)

• Stamp-charging vertical oven type of heat recovery coke oven.

Horizontal Heat-recovery coke oven

1. Battery type and technical parameter

In accordance with the varieties of coal sources and the specific requirements of clients, ACRE offers custom-designed coke ovens with various production capacities, along with comprehensive coking technology and fully integrated equipment solutions.

The table below shows the technical characteristics of typical horizontal heat recovery coke oven coke oven models

Technical Figures of Horizontal Heat-recovery Coke Oven

|

ACRE oven type |

JNHR4.2.1 |

JNHR4.2.2 |

JNHR4.2.3 |

|

Coal per charged (dry basis) |

51.80t |

63.68t |

71.60t |

|

Coking time |

66h |

66h |

66h |

|

Moisture in coal charge |

10% |

10% |

10% |

|

Total length of oven chamber (cold) |

13.64m |

16.64m |

18.64m |

|

Average width of oven chamber (cold) |

3.66m |

3.66m |

3.66m |

|

Total height of oven chamber (cold) |

2.988m |

2.988m |

2.988m |

|

Distance between oven center |

4250mm |

4250mm |

4250mm |

|

Effective dimension of the coal cake |

13,080×3,600×1,100mm |

16,080×3,600×1,100mm |

18,080×3,600×1,100mm |

The latest fourth-generation horizontal heat recovery coke oven (JNHR4.2.2) has been put into operation with a capacity of 2 MTPA in Zhoukou, Henan, and 500,000 tons in Zimbabwe.

2. Structural features and technical advantages of coke oven

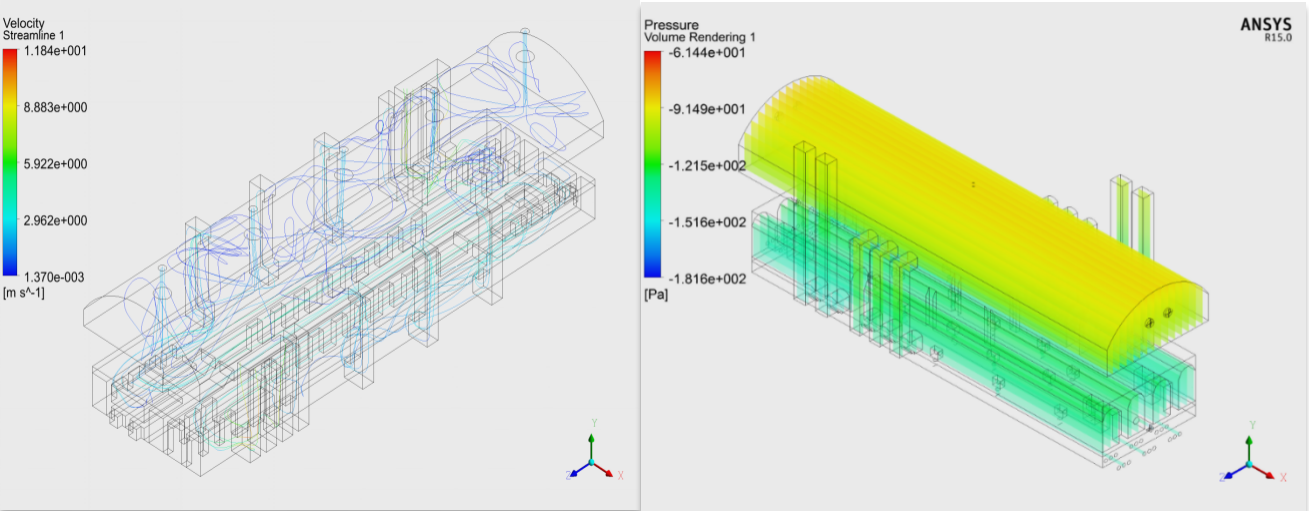

The development and design optimization of horizontal heat recovery coke oven coke ovens have incorporated advanced design tools and methodologies, along with multiple advanced technologies. These ovens have attained international leadership in energy efficiency, environmental performance, service life, and intelligent operation, primarily demonstrated through the following aspects:

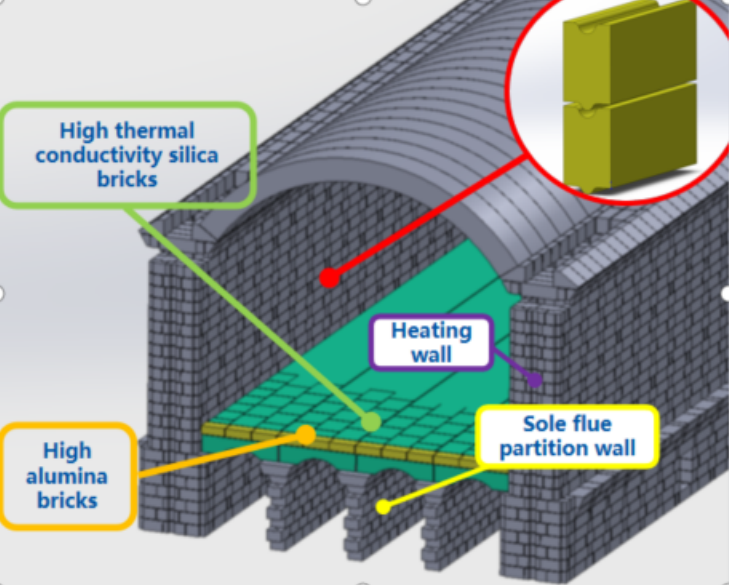

①Refractory block - Optimization for uniform heating in PS-CS direction

The multi-stage spigot of tube bricks at primary air inlet realizes “multi-distribution”of primary air to avoid intensified jetting and to extend combustion passage so as to have a better distribution of combustion air in the coking chamber. Staggered arrangement of primary air inlets and downcomers generates air movement due to pressure difference and improves uniform heat distribution so as for complete combustion of crude gas. The arrangement of single-layer, double C-shaped 4-arch sole flues to improve heating uniformity in PS-CS direction and lateral direction at bottom of coking chamber. This enables: Synchronized control of coking chamber temperature in PS-CS direction; uniform temperature distribution in oven arch space with temperature difference between any two points less than 50 ℃; Complete burning out all combustible substances in flues with temperature control deviation of less than ± 20 ℃

②Refractory block - Improvement of structure strength of refractory block

The coking chamber is paved with high thermal conductivity silica bricks for better heat transfer and higher wear resistance. The coking chamber has double-layer structure at oven ends, with an outer layer of high alumina bricks with good thermal shock resistance and corrosion resistance so as to reduce erosion and wear of the oven ends. The heating wall and sole flue partition wall bricks are provided with tongue-groove locks for higher strength of the entire refractory block.

③ Refractory block - Improvement of refractory block tightness

The coking chamber is paved with high thermal conductivity silica bricks for better heat transfer and higher wear resistance. The coking chamber has double-layer structure at oven ends, with an outer layer of high alumina bricks with good thermal shock resistance and corrosion resistance so as to reduce erosion and wear of the oven ends. The heating wall and sole flue partition wall bricks are provided with tongue-groove locks for higher strength of the entire refractory block.

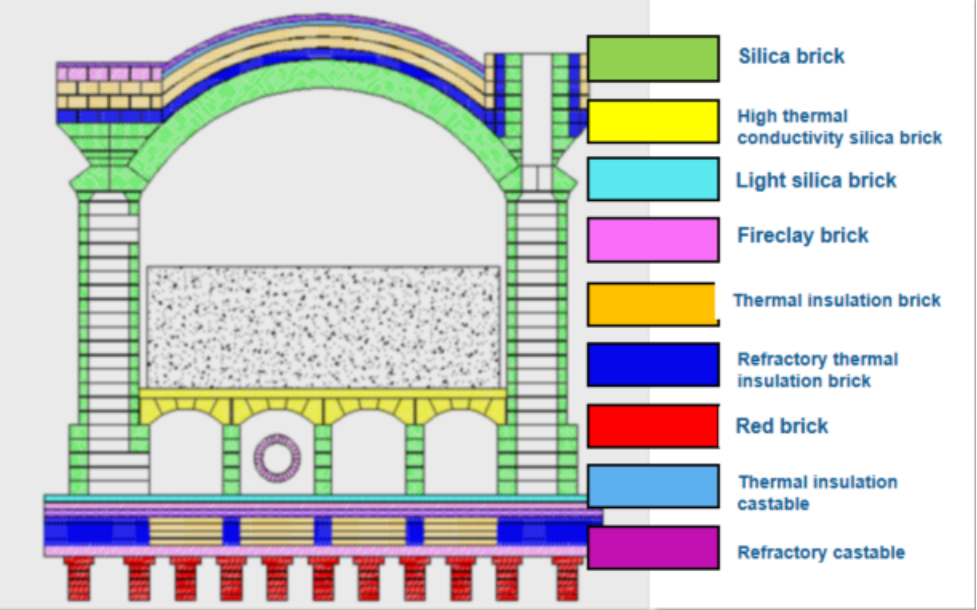

④Refractory block - Optimized combination of various refractory materials for refractory block

The oven bottom is of composite refractory structure, consisting of silica insulation brick, fireclay brick, floating particle brick, thermal insulation brick and red brick. The oven roof is of composite refractory structure, consisting of silica brick, refractory fiber, floating particle brick, thermal insulation brick and castables. With insulation measures, the energy density of flue gas increases by 10%, the average surface temperature of HRO decreases by 25℃. The overall investment in refractory reduces by about 5%, and the service life of the HRO is significantly extended.

⑤Process equipment - Split type oven door with energy-saving and good sealing

Spring-loaded latch fastener plus knife edge with packing flexible sealing ensures good sealing, with little burning loss of coke at oven ends. Oven door lined with castable plus refractory fiber block, instead of conventional lining, with good insulation, and door surface temperature less than 80℃. Oven door is opened/closed by oven machinery automatically.

⑥Process equipment - Self-supporting double GCM and hot flue gas pipes with long service life

The self-supporting high-temperature flue gas piping is Supported by each stand pipe on oven top. Sync. expansion together with refractory block, no need of sliding joint Composite refractory lining consisting of Mullite brick, floating particle brick, thermal insulation brick and ceramic fiber felt, Similar life span to refractory block, with surface temp. lower than 80℃ By adopting cold-end arranged with air regulating device; cancellation of HT valve on branch pipe, No leakage of hot flue gas pipes, maintenance-free.

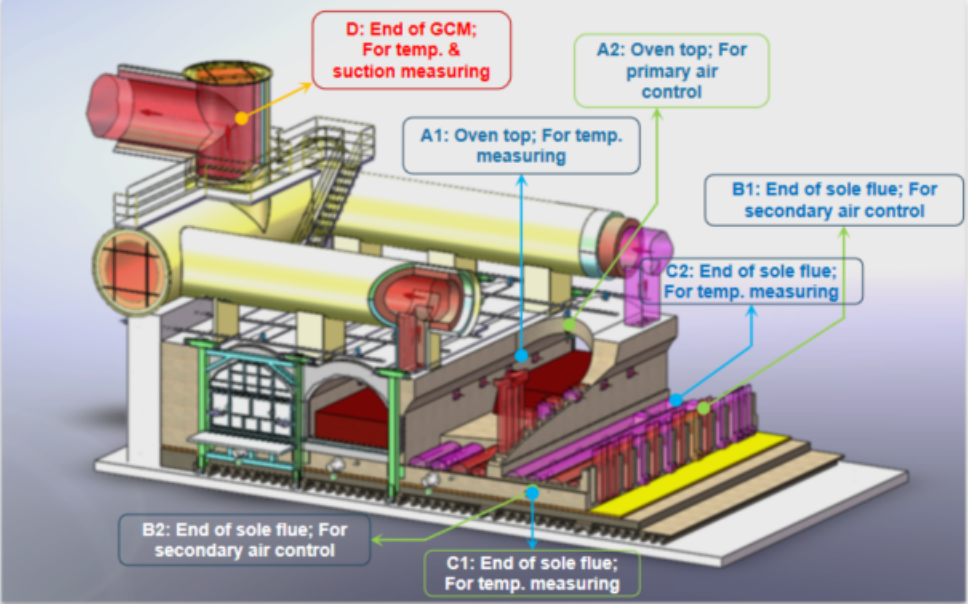

⑦Process equipment - JNHR Automatic measurement & control for battery heating

Temperature-based control mode: Position D: Measurement of suction at the end of GCM, as a guide to control the speed of flue gas fan; Position A1: Measurement of oven arch space temp., to be interlocked with primary air regulating device located at position A2 for temp. control; Position B1: Measurement of temp. at the end of sole flue, to be interlocked with secondary air regulating device located at position B2 for temp. control; Position C1: Measurement of temp. at the end of sole flue, to be interlocked with secondary air regulating device located at position C2 for temp. control.

Technical features and benefits: Temperature-based direct control; Complete burning out all combustible substances in sole flues; Heating system is regulated from cold-end, automatically measured & controlled; Battery temp. control insusceptible to pressure difference of hot flue gas pipes on oven top.

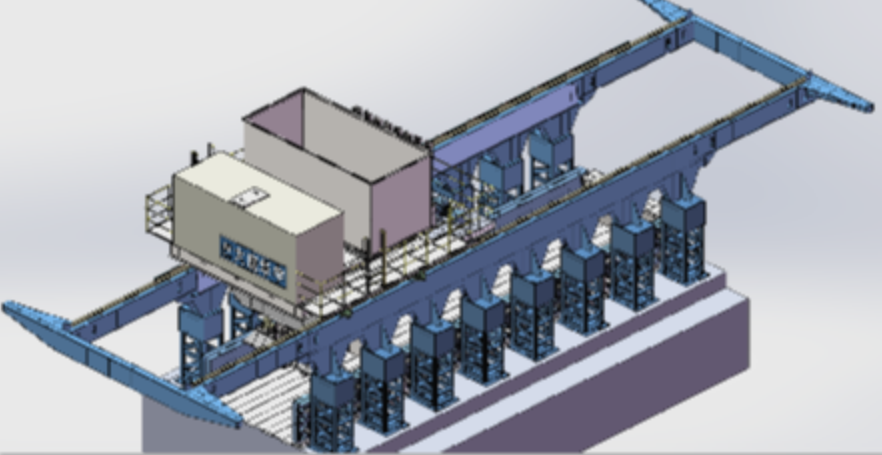

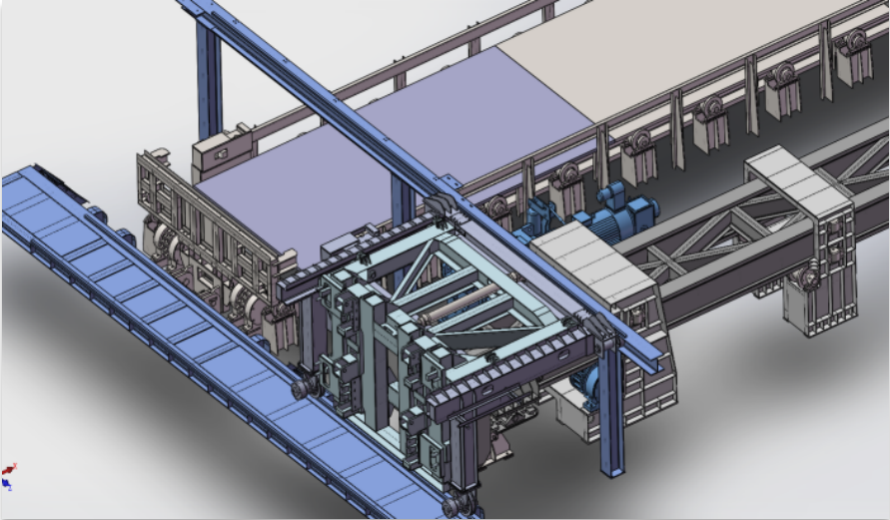

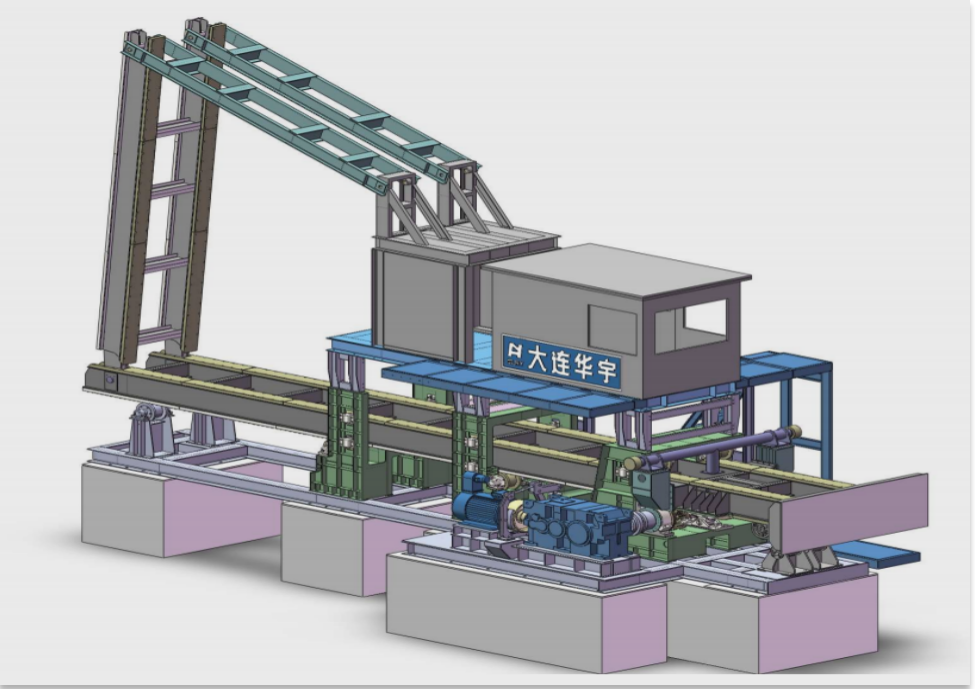

⑧Oven machinery - A pioneering technology combining mechanical hammer stamp and hydraulic compression

High efficiency: Each coal cake stamping <25min; High density of coal cake:0.98~1.0t/m3 (on dry basis); Effect: Hydraulically compressed coal cake with pressed-groove on flat top, reducing coking time by 2 hours

⑨Oven machinery - Charging-pushing machine (C-PM) with two-spot positioning

Achievable full-automatic operation in coordination with oven door equipped with rotatable latch; It is equipped with movable automatic door extractor to realize charging & pushing with two-spot positioning; It is equipped with transversal moving dust collecting hood and machine-carried deduster to collect and treat emission during whole operation and the flue gas with pollutants content less than allowable value is discharged to atmosphere; The stoppers for mechanism of coal charging & coke pushing are equipped with a sealing cover to match with flash plate so as to realize charging & pushing in enclosed condition; The C-PM body stopper coordinating with machine rail foundation can improve positioning accuracy and reduce lateral load to rails; The C-PM reclaims the coal plate loaded with coal cake alternately from one of the two stamping stations to maximize the number of ovens served by the stamping-charging system.

⑩Oven machinery - Flat-type coke receiving car with one-spot positioning

Achievable full-automatic operation in coordination with oven door equipped with rotatable latch; It is equipped with movable door extractor to realize all operations, such as door extracting, coke receving and door closing with one-spot positioning; It is equipped with car-carried deduster to collect and treat emission during whole operation and the flue gas with pollutants content less than allowable value is discharged to atmosphere; Achievable reduction of heat radiation and burning loss of hot coke during conveying; The coke receiving car stopper coordinating with car rail can improve positioning accuracy and reduce lateral load to rails; The coke receiving car can work together with stationary pusher machine to couple with hot coke conveying systems for both new type wet quenching and dry quenching.

⑪Oven machinery - Stationary pusher machine with foldable & double ram beams

It works with flat-type coke receiving car and chute with dust collecting hood to match coke dry quenching (CDQ) process.