Top-charging

1. Battery type and technical parameter

In accordance with the varieties of coal sources and the specific requirements of clients, ACRE offers custom-designed top-charging coke ovens with various coking chamber heights and production capacities, along with comprehensive cokemaking technology and fully integrated equipment solutions.

The table below shows the technical characteristics of typical top-charging coke oven batteries.

Typical Top-charging Coke Oven

|

ACRE Oven type |

JN43 |

JN55 |

JN60 |

JNX3-70-1 |

JNX3-70-3 |

JNX3-76.5-2 |

|

Height of oven chamber (mm) |

4,300 |

5,500 |

6,000 |

6,980 |

6,980 |

7,560 |

|

Average width of oven chamber (mm) |

450/500 |

450 |

450/470 |

500 |

542 |

603 |

|

Oven taper (mm) |

50 |

70 |

60/50 |

50 |

60 |

50 |

|

Length of oven chamber (mm) |

14,080 |

15,980 |

15,980 |

17,640 |

18,640 |

19,640 |

|

Center distance of oven chamber (mm) |

1,143 |

1,350 |

1,300 |

1,500 |

1,500 |

1,650 |

|

Cycle time (h) |

18 |

18 |

19 |

22 |

23~24 |

25.7 |

|

Annual yield of Battery (MTPA) |

60~90 |

80~110 |

100~140 |

120~170 |

150~180 |

180~220 |

2. Structural features and technical advantages of coke oven

The development and design optimization of top-charge coke ovens incorporate state-of-the-art design tools and methodologies. Through the adoption of multiple advanced technologies, these ovens have achieved international leadership in energy efficiency, environmental performance, service life, and intelligence, primarily demonstrated in the following aspects:

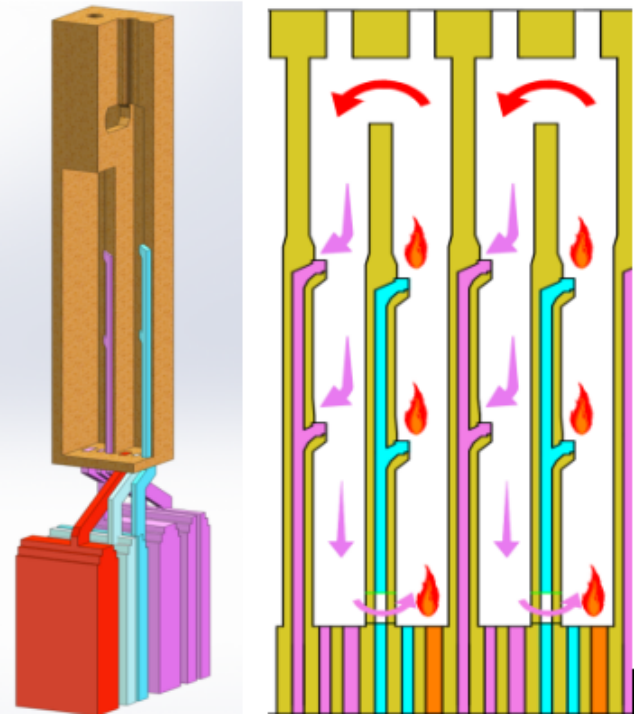

(1)Clean Coke-making and Ultra-Low Emissions

ACRE has developed multiple proprietary emission reduction technologies, including Staged Supply Low-NOx Combustion Technology (LNCT®), Segmented Supply Cold End Control Technology , and Wall Leakage Control Technology (WLCT®). Through simulation-driven optimization of key structures and dimensions in the coke oven combustion system, ACRE have achieved enhanced heating uniformity along both the longitudinal and vertical directions, minimized gas leakage through oven walls, and reduced NOx generation at the source. This integrated approach ensures clean and highly efficient cokemaking. The cross-wall temperature uniformity coefficient of the coke oven can achieve a value exceeding 0.95, with the roof space temperature maintained within 800±30°C. Furthermore, the vertical heating uniformity can be adjusted in real-time from the exterior of the oven. During coal charging and coke pushing operations, visible smoke emissions are virtually eliminated. When heated with mixed gas, NOx emissions can be controlled below 150 mg/m³, and below 300 mg/m³ when using coke oven gas (COG). This performance achieves a world-leading standard.

Segmented Supply Cold End Control Technology

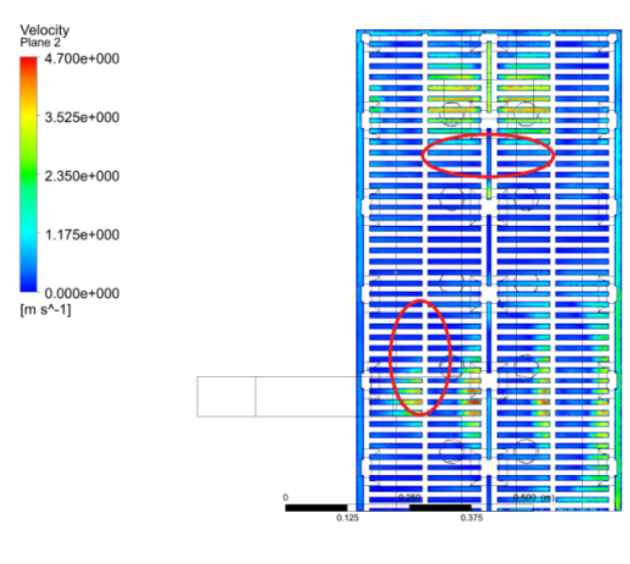

(2)Energy Saving and Consumption Reduction

ACRE have developed a series of advanced technologies including high-integrity oven construction, combined coke oven heating regulation, and high-efficiency regenerator systems. The implementation of new high-performance refractories such as high-thermal-conductivity silica bricks significantly reduces internal gas leakage and heat dissipation, improves heating uniformity and overall thermal efficiency, thereby effectively lowering cokemaking heat consumption. When COG is used for heating, the heat consumption of a top-charge coke oven can be reduced to below 2,350 kJ/kg (for lean gas heating) and below 2,150 kJ/kg (for COG heating), while the thermal efficiency of the oven can achieve over 77%.

Regenerator Gas Flow Distribution

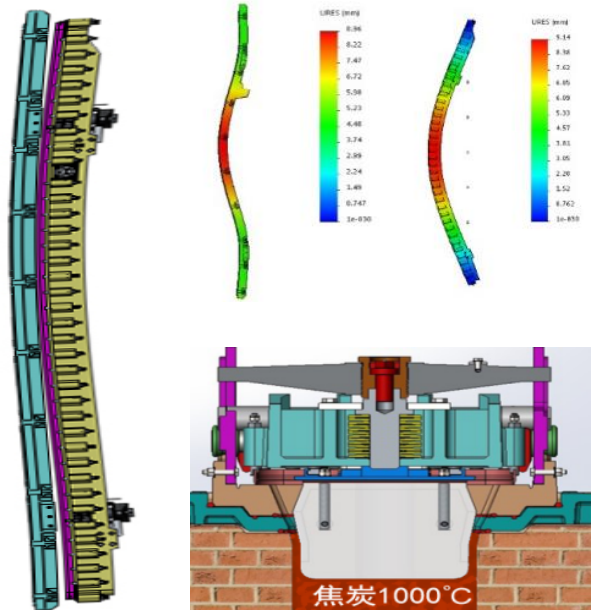

(3)Stable Operation and Long Service Life

Through theoretical calculations and advanced simulation methods, key oven dimensions and the internal structure of the oven body have been optimized. The adoption of large-staggered and embedded structure reduces gas leakage and enhances the structural stability of the refractory block as well as the SUGA value of the oven wall. Furthermore, simulations have been used to optimize the protective force and its vertical distribution applied by bracing system, thereby increasing wall stability while further mitigating leakage. These integrated measures effectively extend the service life of top-charging coke ovens, enabling a campaign life of over 30 years.

Oven bracing System Optimization Technology

(4)Intelligence and Efficiency

The coke oven's intelligent systems optimize production for greater efficiency with less manning, while built-in upgrade interfaces ensure readiness for a fully unmanned future. Through the integrated operation of the Coke Oven Operation Management System, the Coke Oven Machine-Ground Coordination System, and the Coke Oven Chamber Pressure Regulation System, fully automatic coal charging and coke pushing operations are achieved. The automatic heating and temperature monitoring system facilitates intelligent coke oven thermal management. The application of the Coke Oven Machine Coordination System enables unmanned operation of coke oven machines.

The coke oven is equipped with comprehensive safety measures and emergency interlock system. It provides systematic protection through monitoring, intelligent regulation, and automatic emergency handling of hazardous energy sources. Critical equipment operates in either continuous or triggered safety interlock mode, ensuring the fundamental protection of safety and property in case of malfunction and delivering life-cycle safety protection for coke oven operations.

HMI of Intelligent Unmanned Control System for Coke Ovens of Baosteel Zhanjiang Project

(5)Customized Design

ACRE boasts a strong technical team in cokemaking, capable of providing customized coke oven solutions tailored to client requirements.

Custom-designed oven dimensions based on key client criteria—minimizing CAPEX and OPEX.

The optimal heating level height is custom-designed by leveraging the client's coal source characteristics (such as VMs of coal blends and coal cake contraction rate) in conjunction with the combustion chamber structure. This customization reduces graphite formation in the oven chamber and minimizes by-products cracking, thereby increasing the by-products yield.

Customized refractory solutions are developed based on the client's investment budget and operational preferences. It may incorporate advanced materials such as high-thermal-conductivity silica bricks, lightweight silica bricks, and pre-fabricated castables to achieve energy savings and emissions reduction.

The battery heating system is custom-designed based on the client's specific gas conditions, including composition, stability, and calorific value, to minimize production costs.

(6)Rebuilding and Revamping of Existing Coke Ovens

For clients seeking to rebuild or revamp existing coke ovens, ACRE can provide a newly-designed oven proper built to the exact dimensions of the existing battery. This approach allows for the maximum utilization of existing equipment and oven machine. Furthermore, more energy-efficient and environmentally-friendly cokemaking technologies are adopted to reduce both the cokemaking heat consumption and the emission of pollutants such as NOx in new coke ovens.