Battery maintenance

During production, coke oven damage occurred due to various factors. To ensure the normal production of coke ovens and extend the service life, battery maintenance is essential. Coke oven maintenance generally includes hot maintenance and cold repair based on the temperature of oven proper during maintenance.

1.Hot repair

Due to minimal damage to oven proper and less impact on coke production, hot repair is the priority option, including oven top rebuild, jamb brick rebuild, partial rebuild of oven wall, corbel zone repair, cleaning of corbel zone port, replacement of oven sole bricks, heating wall rebuild till oven top, repair of regenerator heating wall, division wall and protection wall, cleaning and replacement of regenerator checker bricks, replacement and gunning of gas riser, replacement and repair of standpipe and gooseneck, reinforcement or replacement of cross tie rod, replacement of flash plate and door frame, ceramic welding, solid (or liquid) air pressure seal, gunning, patching, etc.

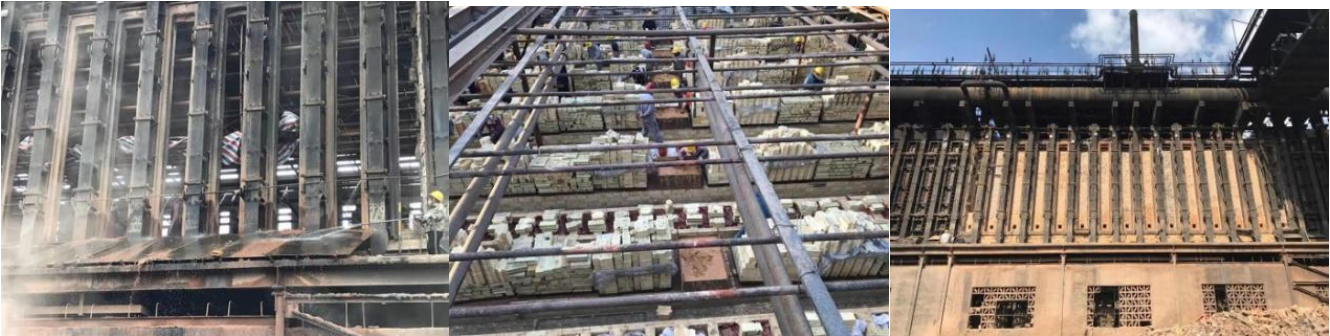

1.1Oven top rebuild and jamb brick rebuild

Oven top rebuild is for solving problems such as uneven oven top, gas leakage on oven top, and high ambient temperature on oven top. Jamb brick rebuild is for solving problems such as burning of bracing system, poor operating environment, and fugitive emissions from coke ovens due to leakage and emission at jamb bricks.

Jamb brick rebuild

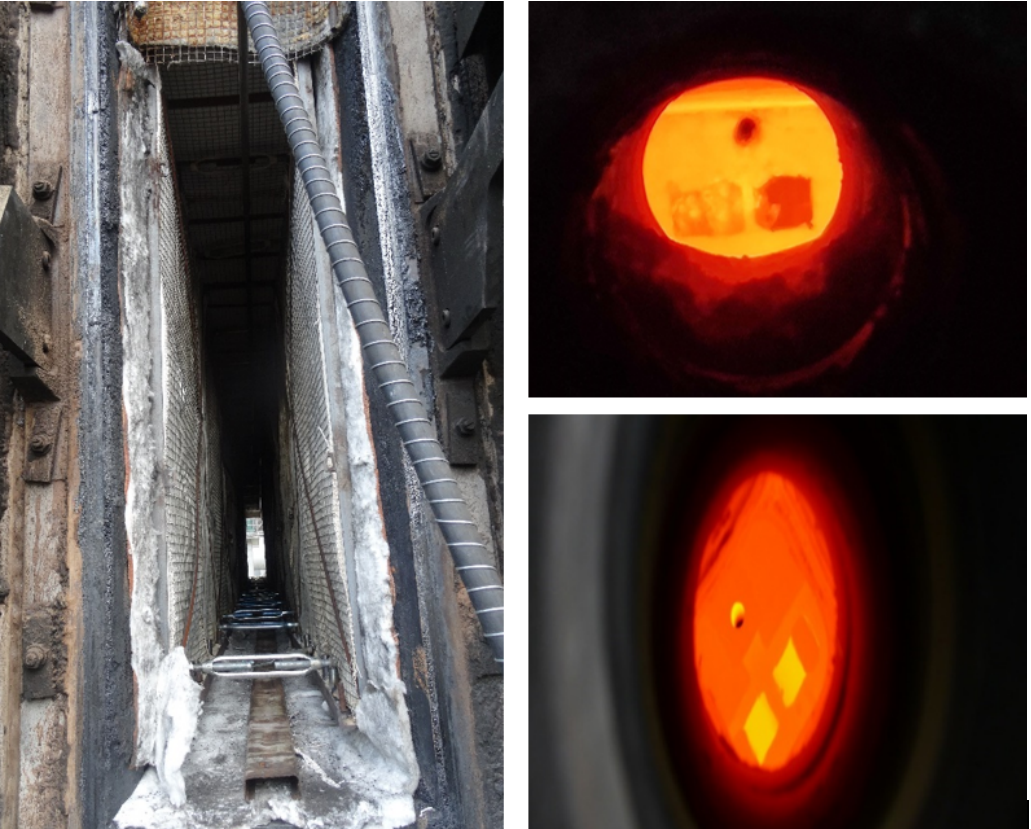

1.2 Ceramic welding

Ceramic welding is used to repair major cracks on oven walls, or defects such as erosion, missing edge, solution cavity or concave surface.

The ceramic welding technology adopted by ACRE boasts outstanding advantages, namely strong bonding between solder and oven proper, high strength, and wear resistance, with the service life of more than one year.

Ceramic welding

Before and after ceramic welding of oven proper

1.3 Partial rebuilding of oven wall

Partial rebuilding of oven wall is used to repair local damage, perforation, or large-scale damage to oven wall. Production can be resumed at an early time.

ACRE adopts zero expansion silicon bricks for partial rebuilding of oven wall. It does not require preheating for maintenance. Un-removed oven wall do not need to be excessively cooled, and can be quickly heated up after maintenance. Ovens can quickly resume production, and no leakage problem occur on the repaired oven wall to meet production requirements.

Before and after partial rebuilding of oven wall

1.4 Replacement of oven sole bricks

Oven sole damage during production is a common problem. Due to long-term wear and tear of the coke oven or oven machines, the oven sole bricks are damaged, which affects the normal production of the coke oven. Therefore, it is necessary to replace the oven sole bricks.

According to the structure features of coke ovens, when replacing the oven sole bricks, maintenance personnel do not need to access the ovens. The heating wall does not need to be cooled down. Production can be resumed on the same day after maintenance. Even if maintenance personnel need to access the oven, when replacing the oven sole bricks, the temperature of heating wall on both sides can still be ensured to be above 850 ℃, ensuring that oven wall is not further damaged due to cooling during maintenance.

Replacement of oven sole bricks

1.5 Heating wall rebuild till oven top

If serious problems occurred such as large cracks, damage, or deformation to oven wall, they can be solved through heating wall rebuild till oven top. The height of heating wall rebuild till oven top is generally from the oven sole to the surface of oven top. The length of heating wall rebuild till oven top depends on the damage degree of oven wall. The work of heating wall rebuild covers several heating flues or even the entire heating walls.

For cases where the oven end is severely damaged or deformed, even causing production to be interrupted, oven end rebuild till oven top can thoroughly solve the problem and resume production to designed capacity.

According to ACRE’s reference projects, after heating wall rebuild till oven top for two 6m batteries, daily coke production increased by more than 1000 tons.

Before and after oven end rebuild till oven top

ACRE once conducted repair of two 5.5m stamp-charging batteries. A through-wall rebuild till oven top was carried out for the whole battery in batches and groups. Each group involved the simultaneous rebuild of up to a dozen of heating walls. After repair, production will be resumed from 29% to 100% and thoroughly solve oven proper problems.

Through-wall rebuild till oven top

1.6 Dredging of corbel zone

Problems of corbel zone ports being melted and blocked affects the normal airflow in heating flues and causes abnormal oven temperature, and further affect production. It’s a common problem encountered in production. According to ACRE’s reference projects, corbel zone ports were dredged for batteries in many coking plants, including dredging of corbel zone port in intermediate of battery. During maintenance, remaining heating flue temperature for repaired heating wall will be above 850 ℃ except for the construction area, providing maximum protection for the un-repaired battery walls.

1.7 Checker brick replacement

Dust accumulation or deformation of checker bricks due to melting will increase the resistance of regenerator, uneven airflow distribution, and affect the normal heating of coke oven. If such problems can not be solved by air purging, it is necessary to replace the checker bricks in regenerator.

ACRE has replaced checker bricks for multiple types of coke ovens, including the replacement of checker bricks for partition-type regenerator.

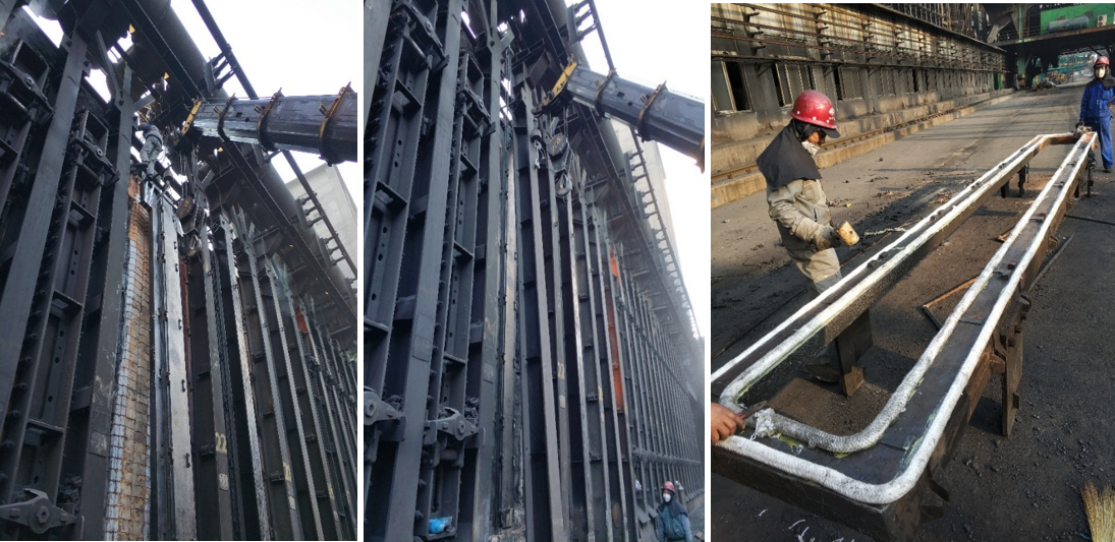

1.8 Replacement of buckstay, flash plate and door frame

The maintenance of bracing system, including buckstay, flash plate and door frame is important to coke oven. If bracing system is damaged and cannot protect the oven proper, it should be repaired or even replaced to prevent oven proper being further damaged.

Replacement of buckstay, flash plate and door frame

Based on condition of oven proper, it can be judged whether the tonnage of large and small springs shall be redesigned and calculated after maintenance. Instruction is given to the adjustment of bracing system to protect the bracing system from abnormal damage.

2 Coke oven cold repair

Cold repair of coke oven includes repair before coke oven restart and coke oven major repair.

2.1 Repair before restart of coke oven

During coke oven shutdown, irreversible damages will occur such as fractured oven wall bricks and mortar joints. These damages will impose great safety and environmental risks for the resumption of coke oven production. Before restarting, it is necessary to repair the damage on various parts of the coke oven to eliminate hazards and restore production.

The priority during maintenance is the maintenance of cracks on regenerator and oven wall. Several solutions were given by ACRE for repairing wall cracks ranging from 1-3mm to 30-40mm. Based on actual situation of coke oven, redesign and maintenance for parts of coke oven will be carried out. Equipment of the coke oven will be inspected, replaced, and repaired simultaneously.

After maintenance, smooth coke pushing is achieved for all ovens. There was no emission from the oven top and oven door. No black smoke is emitted from chimney. No improvement is required for chimney flue gas treatment system. Pollutants in flue gas can meet regulatory requirements, with SO2 emission below 30mg/m3, NOx emissions below 150mg/m3, and particulate matter emissions below 15mg/m3.

Production in good condition after cold repair

2.2 Major repair of battery

In case of oven proper seriously damaged, and difficult temperature rising, causing abnormal production, it's time to conduct major repair of battery and thorough repair of oven proper.

The major repair of coke oven usually starts by cooling the entire battery to room temperature, reserving battery foundation, dismantling and rebuilding of refractory blocks, repair or replacing of bracing system, process equipment and oven machines based on actual situation, then igniting the oven until coke oven production is restored. The advantages include favorable construction condition, high quality repair, few potential hazards, and prolonged battery life.